How to Know It’s Time for an Electric Motor Replacement

Almost every industry, including manufacturing, automotive, aerospace, HVAC, and more, all depend on electric motors for their daily operations. The motors provide a means of efficiency to get final products and services completed faster, which leads to higher profits and satisfied stakeholders. So obviously electric motors are vital for many businesses, yet so many owners don’t know when they should replace their motors. Continue reading to learn how to know it’s time for an electric motor replacement.

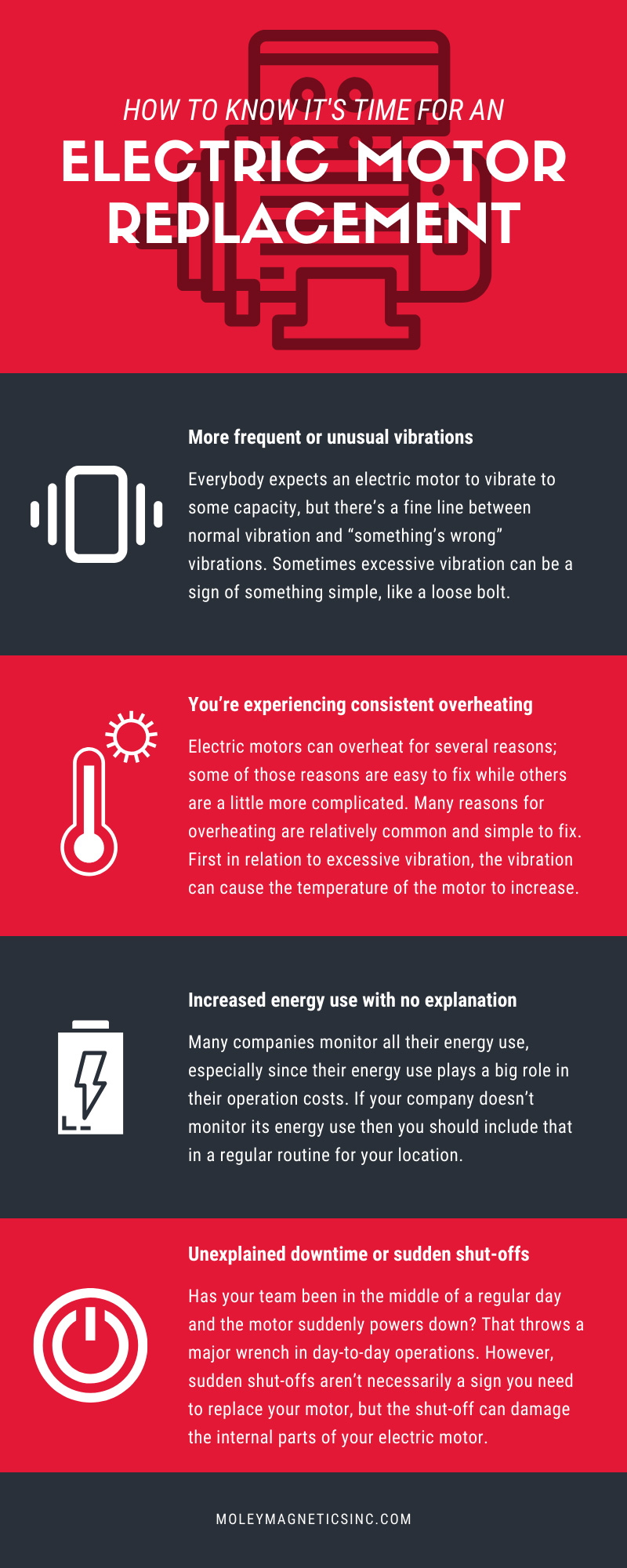

More frequent or unusual vibrations

Everybody expects an electric motor to vibrate to some capacity, but there’s a fine line between normal vibration and “something’s wrong” vibrations. Sometimes excessive vibration can be a sign of something simple, like a loose bolt. On the other hand, some vibrations can be a red flag indicating that the motor needs a repair or needs to be replaced.

You should know that not all vibrations are the same. Your motor may have consistent or pulsating vibrations, both of which can mean something different. A consistent vibration is usually a little easier to detect and identify, while a pulsating vibration can be difficult to locate. Neither type of vibration is better or worse than the other. You should take the issue seriously, though, because you either need to tighten a bolt or hire a professional maintenance worker, or your motor may have permanent damage.

You’re experiencing consistent overheating

Electric motors can overheat for several reasons; some of those reasons are easy to fix while others are a little more complicated. These first three reasons for overheating are relatively common and simple to fix. First in relation to excessive vibration, the vibration can cause the temperature of the motor to increase. Second, your motor could need a mere deep cleaning, which you should be doing anyway. Excessive dust can significantly reduce the ventilation of your motor, ultimately retaining the heat inside. Third, you may be overloading your power source, whether you’re going through a generator or not, motors take quite a bit of power to operate. In some cases, you just need an additional power source or a new power source. If you’re pulling more voltage than the power source can suffice, the motor will be working harder and you’ll likely overload the circuits.

Another reason your motor might be overheating is if you’re using it for a new production line and the motor is required to use more power than usual. While many motors will work in different settings, you should consult with a motor manufacturer before using a motor in a different area than before. Otherwise, you’ll run the risk of overheating and causing permanent damage to your motor.

Increased energy use with no explanation

Many companies monitor all their energy use, especially since their energy use plays a big role in their operation costs. If your company doesn’t monitor its energy use then you should include that in a regular routine for your location. However, assuming that you are monitoring your energy use, if you begin seeing that your energy use is increasing but you’re proceeding with business as usual, something’s wrong. A common reason for this is a decrease in motor performance, which typically indicates that your motor needs professional maintenance, or you might need a replacement.

Luckily it’s rather simple to identify if your motor is lacking in performance. The materials and efficiency of your motor depend on everything working as it should. The moment something is wrong with your motor, you’ll begin to notice that your regular operations are taking longer than usual. In other words, you’ve seen a drop in efficiency, which should be a red flag for any business owner. However, before you stress yourself out about why energy and efficiency is struggling, you should check your company’s motors.

Unexplained downtime or sudden shut-offs

Has your team been in the middle of a regular day and the motor suddenly powers down? That throws a major wrench in day-to-day operations. However, sudden shut-offs aren’t necessarily a sign you need to replace your motor, but the shut-off can damage the internal parts of your electric motor. If the internal components of a motor are damaged, there’s a good chance that you’ll have to replace the entire motor. You could get the damaged components swapped out, but that’s usually less cost-effective than replacing the motor altogether.

Electric issues are the most common reason for unexpected downtimes when it comes to electric motors. For instance, you may be overloading the circuits which can cause the motor to work harder and eventually overheat. The best way to counteract sudden shut offs is to ensure you have an adequate power source. However, if your electric motor is still shutting off unexpectedly, the interior circuits may be permanently damaged and you may need a new motor.

Whether you’re new to an industry that regularly uses electric motors or you’ve been in it for decades, you need to know when it’s time for an electric motor replacement. Not to mention, your business can’t afford to experience unexpected downtimes and overheating motors. In addition, your crew shouldn’t have to work with unreliable equipment, as it makes their jobs more difficult to complete. Lastly, your customers don’t deserve to hear, “Sorry, our equipment went down.” Of course, accidents are going to happen, but you can control most of the issues by replacing your electric motors.

Here at Moley Magnetics, our family-owned business began in our garage as a motor repair shop and we continue to pride ourselves on our great work. In fact, we’ve continued to grow as one of the most trusted motor repair shops and suppliers in the nation. We supply electric motors to several different industries, but we’re also able to supply custom electric motorsfor our customers that need something that’ll fit their unique needs. We believe your motors should work for you, not against you, and that’s why we only offer the highest-quality products to our customers. We don’t believe in pinching pennies or cutting corners just to save a buck. If we wouldn’t use the motor ourselves, we certainly wouldn’t sell it to you. If you’re ready to replace your electric motors, contact us today. Our family and team of experts will be happy to help you identify the best motor for your company.