Magnetic separation has been around for decades, and people traditionally used electromagnetics for separation until permanent magnets became more available and affordable to produce. Industries such as scrap yards, mining, pharmaceuticals, biochemistry, manufacturing, and food all use magnetic separation regularly because it’s effective and efficient. However, it’s important to have a general understanding of magnetic separation, how it’s used, and the types of magnets. Our guide of magnetic separation: the basics, will break it all down.

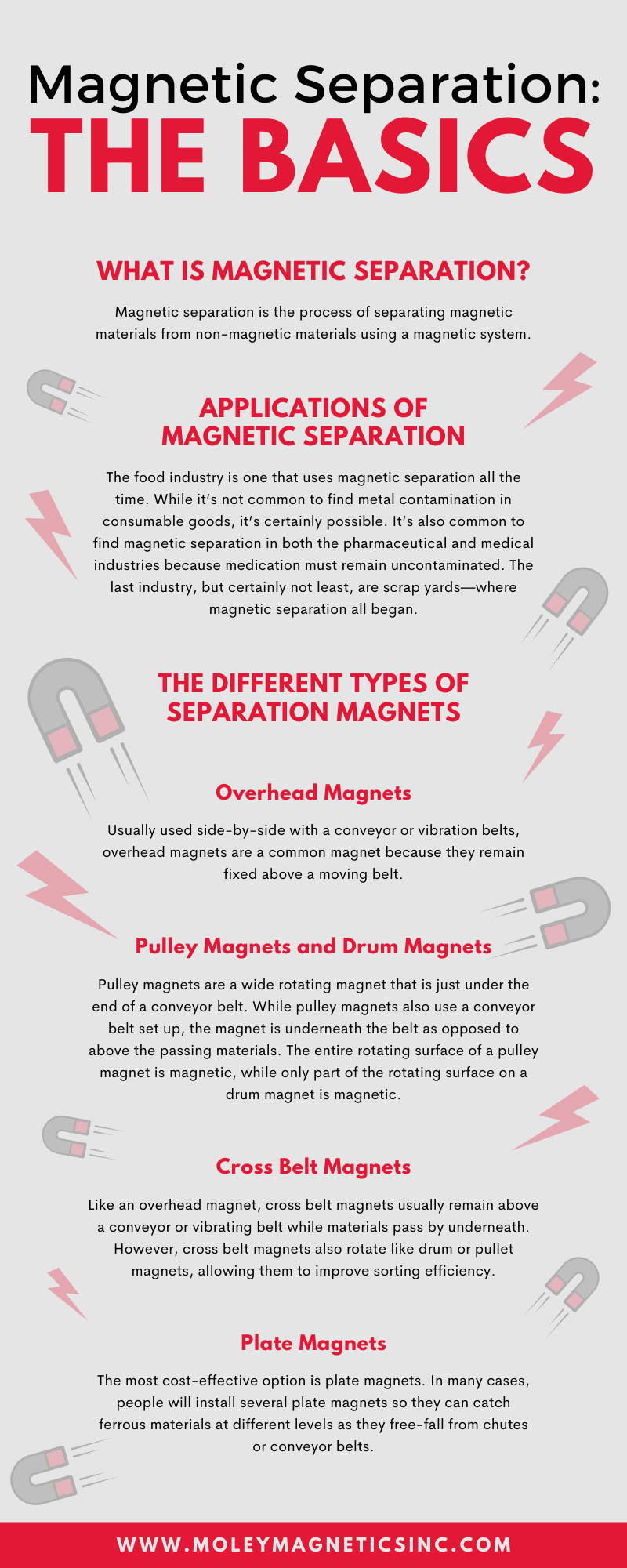

What is Magnetic Separation?

Magnetic separation is the process of separating magnetic materials from non-magnetic materials using a magnetic system. After World War II, this process became popular in scrap yards to separate metal particles from vehicles; however, the process is more sophisticated than that. In fact, one of the major benefits of magnetic separation is that the magnets can separate micro-sized particles of ferrous material. The fact that these magnets can separate such small particles makes it a favorable piece of machinery in food production to ensure there are not any metal contaminants from manufacturing.

Applications of Magnetic Separation

The food industryis one that uses magnetic separation all the time. While it’s not common to find metal contamination in consumable goods, it’s certainly possible. So, most food-related suppliers put their products through magnetic separation to ensure there was no contamination during the manufacturing process or while transporting the goods.

It’s also common to find magnetic separation in both the pharmaceutical and medical industries because medication must remain uncontaminated. For example, we all go to the doctor and take medicine to be healthier. However, if the medicine is (or was) contaminated by metal particles at any point, the medicine isn’t going to help us—if anything it might harm us more.

Those who work in mining are often familiar with magnetic separation because they regularly sort materials. Miners most commonly sort materials based on the amount of iron ore in a mixture. They sort mixtures based on one of the three levels of magnetism: ferromagnetic, paramagnetic, and diamagnetic minerals. Each of these minerals reacts differently to magnets. For example, ferromagnetic minerals are strongly receptive to magnets. On the other hand, paramagnetic minerals faintly react to magnets, and diamagnetic minerals deter from a magnetic force.

The last industry, but certainly not least, are scrap yards—where magnetic separation all began. There are two main uses for magnetic separation in scrap yards. First, magnets help workers separate mixtures of course, and second, they help workers sort materials. For example, a scrap yard that aims to recycle as much as possible would want to ensure they’re getting all ferrous materials separated so their recycling process doesn’t become contaminated. In addition, scrap yards tend to have a lot of large and heavy pieces that they need to move. For instance, the scrap yard may only handle smaller ferrous pieces such as nuts and bolts, while another scrap yard may handle entire vehicles. The latter scrap yard would likely use a crane with a heavy-duty magnet to move the entire vehicle.

The Different Types of Separation Magnets

Overhead Magnets

Usually used side-by-side with a conveyor or vibration belts, overhead magnets are a common magnet because they remain fixed above a moving belt. For instance, while a conveyor belt moves materials along, once the materials begin to pass underneath, the overhead magnet will attract any ferrous materials. Any non-ferrous materials will continue down the conveyor belt and ultimately become sorted.

Pulley Magnets and Drum Magnets

Pulley magnets are a wide rotating magnet that is just under the end of a conveyor belt. While pulley magnets also use a conveyor belt set up, the magnet is underneath the belt as opposed to above the passing materials. For example, as materials move along on the conveyor belt, the pulley magnet below will attract ferrous materials and disperse them into a separate sorting bin. The non-ferrous materials, on the other hand, will reach the end of the conveyor belt and cascade into their own separate bin.

While drum magnets and pulley magnets are similar, there’s one main difference. The entire rotating surface of a pulley magnet is magnetic, while only part of the rotating surface on a drum magnet is magnetic.

Cross Belt Magnets

Like an overhead magnet, cross belt magnets usually remain above a conveyor or vibrating belt while materials pass by underneath. However, cross belt magnets also rotate like drum or pullet magnets, allowing them to improve sorting efficiency. For instance, cross belt magnets fix the problem that overhead magnets would face—that is, getting full before a worker can buy valtrex overnight clear ferrous materials off the magnet to free up space. Instead, as items move along the belt, the cross belt also attracts ferrous materials. Those same materials then move along the cross belt before cascading into a deflector chute.

Plate Magnets

The most cost-effective option is plate magnets. In many cases, people will install several plate magnets so they can catch ferrous materials at different levels as they free-fall from chutes or conveyor belts. In some cases, manufacturers or scrap yards will choose to use plate magnets in addition to one or more options, just to ensure they’re catching everything.

Magnetic separation is one of the most effective and efficient ways to sort ferrous and nonferrous materials. In fact, it’s such an efficient method that several industries regularly use it to ensure quality. The hard part is deciding which magnet is right for your job as some people only need one of these magnets while others need several.

Whether you need a set of plate magnets or a magnetic drum separator, Moley Magnetics has what you need. Even if you don’t know what you need, our excellent customer service team can help you find the magnet that’s best for your job. Plus, if you have an old magnet, shears, grapples, and so on, we do repairs too. As a family-owned business that started in our garage years ago, we believe in hard work and value honesty and integrity. So, contact us today for all your magnetic needs, and our team will be happy to serve you!