How To Help Your Electric Motor Last Longer

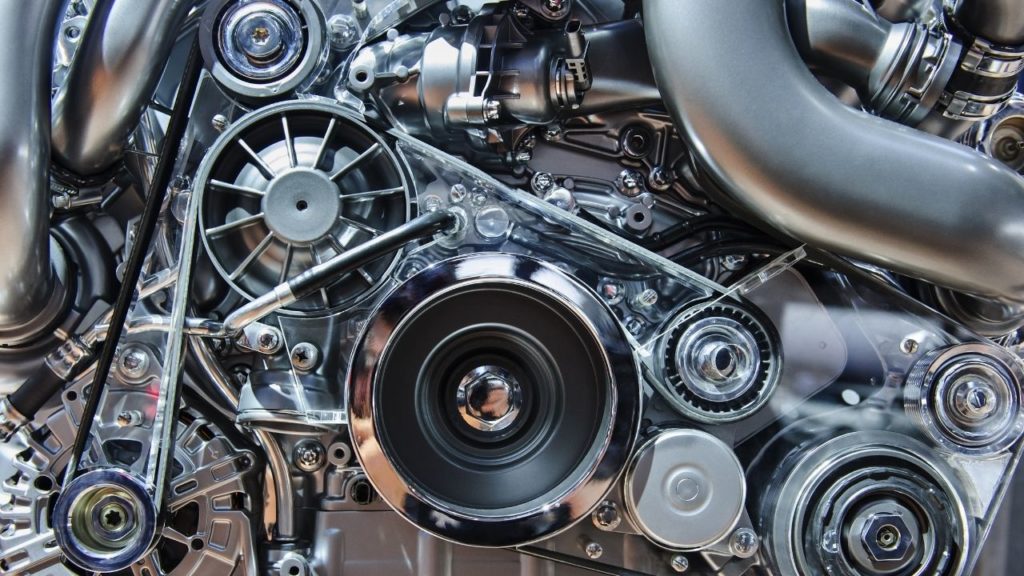

Equipment is an investment, and like any investment, it’s one that you hope to maximize your return on. One piece of equipment that almost no facility can do without is some variety of electric motor. Whether it powers a CNC rig, a less sophisticated piece of heavy machinery, or anything in between, the industrial world needs motors.

Since electric motors are such a big part of a facility’s operations, it’s important they last for a while. A medium-horsepower DC motor should have a lifespan that falls somewhere between 5,000 and 10,000 hours. If you ran that motor for eight hours a day every workday, that would be somewhere between three and five years. Motors of different sizes and applications have different lifespans, of course. But the common thread uniting them is that you want to keep them running for as long as possible before it’s time for their retirement and replacement. Here’s how to help your electric motor last longer, no matter its role, and how to make the most of your investments.

How To Safely Use an Electric Motor

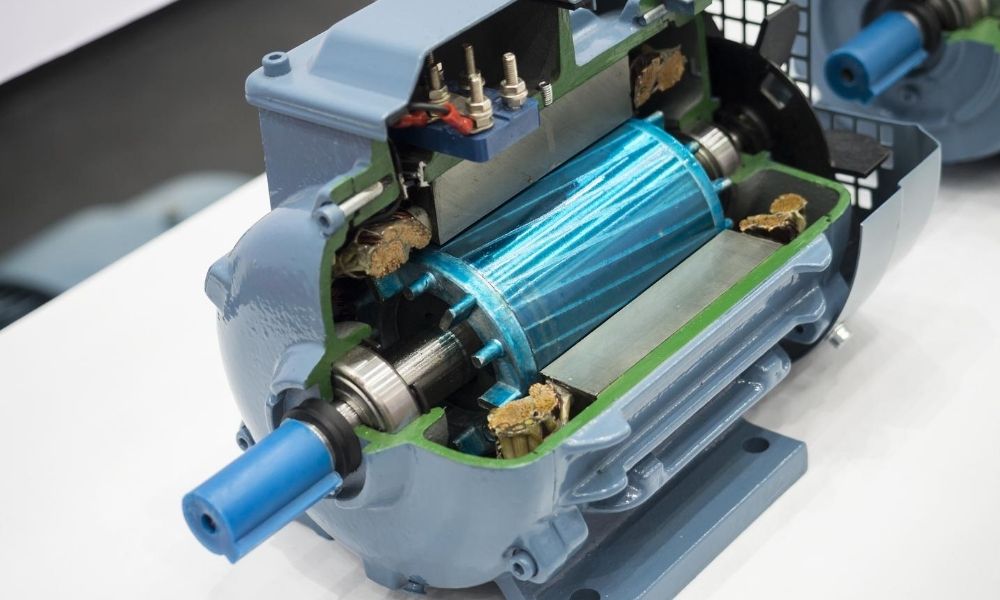

Electric motors transform electrical energy into mechanical energy by harnessing magnetic fields to apply torque, or rotational force. Electric motors can be brushed, meaning they use additional parts to generate a current, or brushless, which use permanent electromagnets instead. They can run on direct current or alternate current. Some electric motors are even “unrolled” and apply linear force rather than rotational force. No matter the differences in specifications, operating an electric motor—or any electric equipment—requires the utmost safety. While most people can operate their electric motors for everyday use without incident, most safety issues arise during attempts to repair them. In this guide to how to safely use an electric motor, we will go over some of the dos and don’ts of motor operation and maintenance for all the different variations of electric motors.

How To Choose a Spindle Motor for Your Application

Human error has been the sworn nemesis of progress in the field of precision tasks. As attention to detail has evolved to a non-negotiable demand for detail, the minute variations and vacillations in human-operated machinery have become unacceptable. For this level of manufacturing, human-aided automation has been a boon to achieving the necessary precision. Computer numerical control, or CNC, is an automation process that uses a coded program to perform high-precision tasks involving tools such as drills, lathes, grinders, and even torches or jets. Most modern embroidery is done not by hand but by CNC, and the 3-D printers that are changing today’s world rely on the latest in CNC technology.

Reasons Your Electric Motor Is Overheating

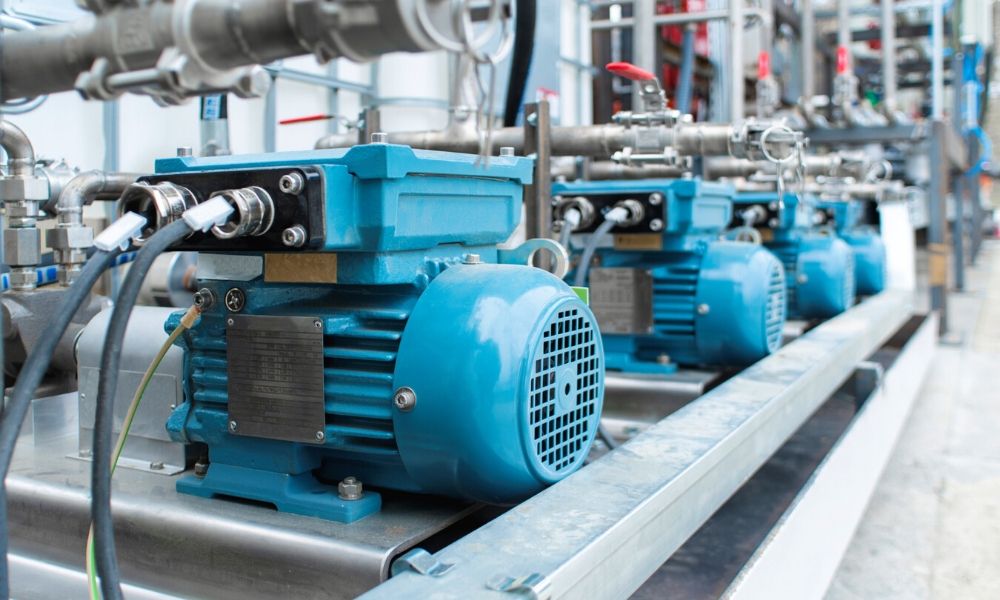

With the number of machines companies depend on these days for operating their business efficiently, such as fully enclosed hydraulic magnets it’s no surprise that electric motors are a hot topic. Without electric motors, many companies would see dramatic dips in efficiency and profitability. In fact, some companies wouldn’t be able to operate at all without electric motors. Part of owning electric motors is proper and frequent maintenance. Despite having a maintenance routine, many electric motor owners experience overheating at some point. Overheating forces operators to deactivate the motor temporarily which obviously results in downtime and a decrease in productivity. There are dozens of potential reasons your electric motor is overheating. We’re going to cover the most common reasons in our comprehensive guide below; read on to learn more.

How To Check If an Electric Motor Is Going Bad

For centuries, we’ve seen tremendous innovation in industrial operations. Our ancestors worked diligently to find solutions to the sluggish processes they experienced, which ultimately led us to the development of motors and automation. Today, countless companies rely on electric motors to make their operations more efficient. While motors have certainly made significant improvements to the operations of businesses, companies also must maintain their motors to avoid downtime. In order to prevent future downtime and inefficiencies, you must know how to check if an electric motor is going bad. If you know how and what to look for in a motor, you can take action early and prevent your motor from going down and potentially getting damaged. If you’d like to learn more, you can read our comprehensive guide below.

The Advantages of Custom Electric Motors

A lot of companies try to sell you something they claim to be custom that isn’t actually custom at all––Moley Magnetics doesn’t do that. Our customers love purchasing custom motors from us because we know what we’re doing, have the years of experience to back it up, and guarantee top-quality. If you’re still skeptical, check out some of the advantages of a custom electric motor below.

How to Know It’s Time for an Electric Motor Replacement

Almost every industry, including manufacturing, automotive, aerospace, HVAC, and more, all depend on electric motors for their daily operations. The motors provide a means of efficiency to get final products and services completed faster, which leads to higher profits and satisfied stakeholders. So obviously electric motors are vital for many businesses, yet so many owners don’t know when they should replace their motors. Continue reading to learn how to know it’s time for an electric motor replacement.

(more…)

The Difference Between AC and DC Motors

Many individuals confuse AC and DC motors because they’re similar in functionality; however, they get their power from different sources. When it comes to fixing your electric motors or purchasing replacements, you should know the difference between AC and DC motors. Keep reading to learn more.

(more…)

What to Consider When Choosing an Electric Motor

Electric motors allow businesses to operate more smoothly by having more-efficient machines. The motors help machines of all different kinds operate at their best, and it’s critical that each machine has the appropriate motor. If a machine’s motor doesn’t have enough torque or voltage available, the motor could overheat or even damage the machine. However, there are many other factors to keep in mind before purchasing a new electric motor. So if you’re in the market for an electric motor, we strongly encourage you to continue reading so you know what to consider when choosing an electric motor.

(more…)Moley Magnetics, Inc. Application Story | Selecting a Motor

Application Story Situation: Moley Magnetics, Inc. had been working on quoting a customer on a motor and variable frequency drive that would be used in a kiln application; with extremely high temperatures and 100% humidity.

Spec: The customer was requesting that the motor be inverter duty vs. inverter rated.

Moley Response: Upon further questioning, we were able to explain to the customer that a true inverter duty motor is used in applications where positioning is critical to the application. (more…)