Industries That Rely on Mechanical Seals

Across the many industrial sectors that employ centrifugal pumping systems, gland packing, in which a tightly wound rope prevents fluid leakage, is often the sealing material of choice. Simple, affordable, and easy to install, countless operators are content to rely on packing to maximize the performance of their pumps. But right now, we’re going to talk about the instances where packing isn’t enough.

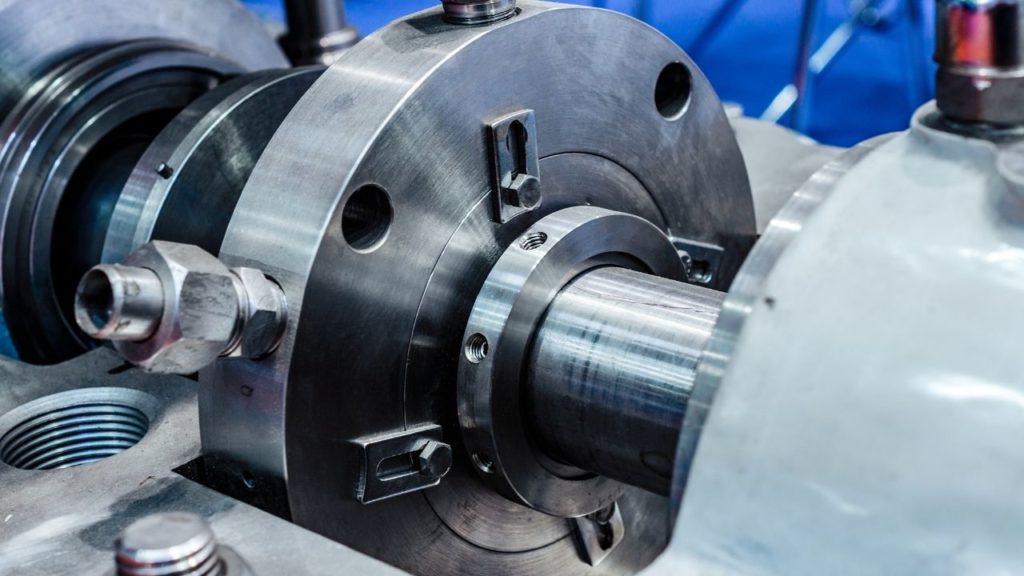

A long-lasting and reliable alternative to gland-packing materials, mechanical seals connect to the rotating shaft of a pump, where they prevent the circulating fluid from leaking around the pump’s impeller. This is of twofold importance: leakage means a loss of what can often be a very valuable fluid, and that same leakage can also damage the pump’s components. Additionally, mechanical seals don’t merely protect a pump from the fluid—they protect the fluid itself, sheltering liquids and gases from outside contaminants.

It’s true that mechanical seals cost more than gland packing—in some cases, such as double mechanical seals, they cost much more. However, thanks to the money facilities save by not repeatedly replacing packing and the savings that come from not losing valuable material to leakage, the higher up-front costs of premier mechanical seals pay off in the long run. That’s why there are so many industries that rely on mechanical seals no matter their expense. Today, we’ll take you on a tour through those industries and explain exactly why they rely on mechanical seals. Read on for more.

Oil & Gas

The importance of mechanical seals looms large in the oil and gas industry, where producers and refiners can’t afford to waste a drop of the petroleum and natural gas products that go on to power our lives. Crude oil, despite its name implying a rough and unfiltered nature, can’t withstand contamination from outside contaminants. Mechanical seals keep those adulterants out of the pump and out of the oil. The same goes for natural gas, where it’s especially important to maintain the purity of a gaseous and flammable fluid.

Power Plants

As we move from the refinement of energy material to the production of energy, we nonetheless continue to find mechanical seals hard at work. Power plants, particularly the many coal-fired plants on our national power grid, employ mechanical seals throughout their pumping systems. Even given the durability of mechanical seals, coal proves challenging to pumps and process piping. Suspended solids—and highly abrasive ones at that—are commonplace among fluids when working with a “dirty” fuel such as coal, and these abrasives can do damage to pumps, pipes, and even seals. Handling heavy fluids such as these requires a commitment to particularly durable seals. Moley Magnetics has partnered with John Crane to provide exactly that. Our partnership provides industrial mechanical seals of unrivaled quality, featuring reliable construction and materials that can stand the toughest tests.

Mining

When we mine for valuable natural resources such as iron and coal, how do miners get them from the earth below to processing at ground level? It’s not via a mine cart or wheelbarrow. Instead, miners set up pipelines that carry a slurry—a mixture of the desired minerals and water. By temporarily transforming solids to a liquid, it’s possible to pump the goods to their destination, where further processing removes the water and reduces the slurry back to the minerals. Of course, a mineral slurry is one of the most viscous and abrasive fluids a centrifugal pump can work with. Particularly, the oil sands that travel from the fields of Alberta and North Dakota are notorious for how much extensive refining they require, and when it’s a matter of extracting the most petroleum possible from this material, no one can afford to do anything but maximize that extraction. In such a situation, gland packing is an especially insufficient bulwark against leakage and contamination. It takes well-built and well-lubricated mechanical seals to handle slurry as it works its way through centrifugal pumps en route to refining.

Pulp & Paper

Even as more newspapers go fully digital, we’re not living in a paperless world just yet. The paper industry also relies on slurries—in this case, the pulp that becomes reams of paper—and in turn, its pumping systems rely on mechanical seals to keep outside pollutants out of the pulp. One can easily imagine the havoc that pulp could wreak on the components of a pump without the right sealing techniques. Mechanical seals prevent that havoc, and everything from our newsprint to our hardcover books are better off for it.

Pharmaceutical Production

Ensuring the quality of pharmaceuticals as they head to market is an absolute requirement of the drug industry. Mechanical seals, and double mechanical seals, in particular, are a means to that end. In fact, even mechanical seals can be “pharmaceutical-grade,” in a manner of speaking. Whereas most mechanical seals use a thin layer of oil as a lubricant, pumping systems in the pharmaceutical industry often instead use what we call “dry seals,” which replace the lubricating oil of “wet seals” with a dry gas that uses the grooves of the seal to create the necessary pressure that prevents leakage of fluids. This configuration provides the greatest protection against contamination of any sort.

Automotive Industry

Among the industries that rely on mechanical seals, it’s arguably our automobiles with which people are most familiar. Far from the industrial-level processes such as pumping slurry out of mines or manufacturing pills, the manufacture of automobile engines relies heavily on using mechanical seals to provide long-lasting and reliable sealing under the hood—an application where constant packing and repacking is simply not an option. The cooling pump of a motor circulates valuable coolant fluid but can’t spare it to leaks. For this task, the Big Three and foreign manufacturers alike turn to mechanical seals to provide the necessary safety and durability.

Get Sealed With Moley

Moley Magnetics is proud to provide mechanical seals—single and double, wet and dry, pusher and non-pusher, back-to-back, face-to-face—to our partners in industry. Shop our catalog for the finest in John Crane mechanical seals and more.