Safety Risks Faced by Recycling Workers

When someone considers working in the recycling industry, they usually don’t consider the hazards involved in the career. Additionally, the managers and decision makers at a recycling facility might not be aware of the safety hazards their workers face day in and day out. It’s important that everyone in the recycling industry is fully aware of safety risks, how they can prevent accidents, and how to keep themselves safe. While building awareness sounds simple enough, it’s your responsibility as the facility manager to execute a training plan to ensure everyone is aware of the risks. However, you can’t build a training plan if you don’t know what the risks are to begin with. Our experts put together a guide discussing the safety risks faced by recycling workers for your reference. Read on to learn more.

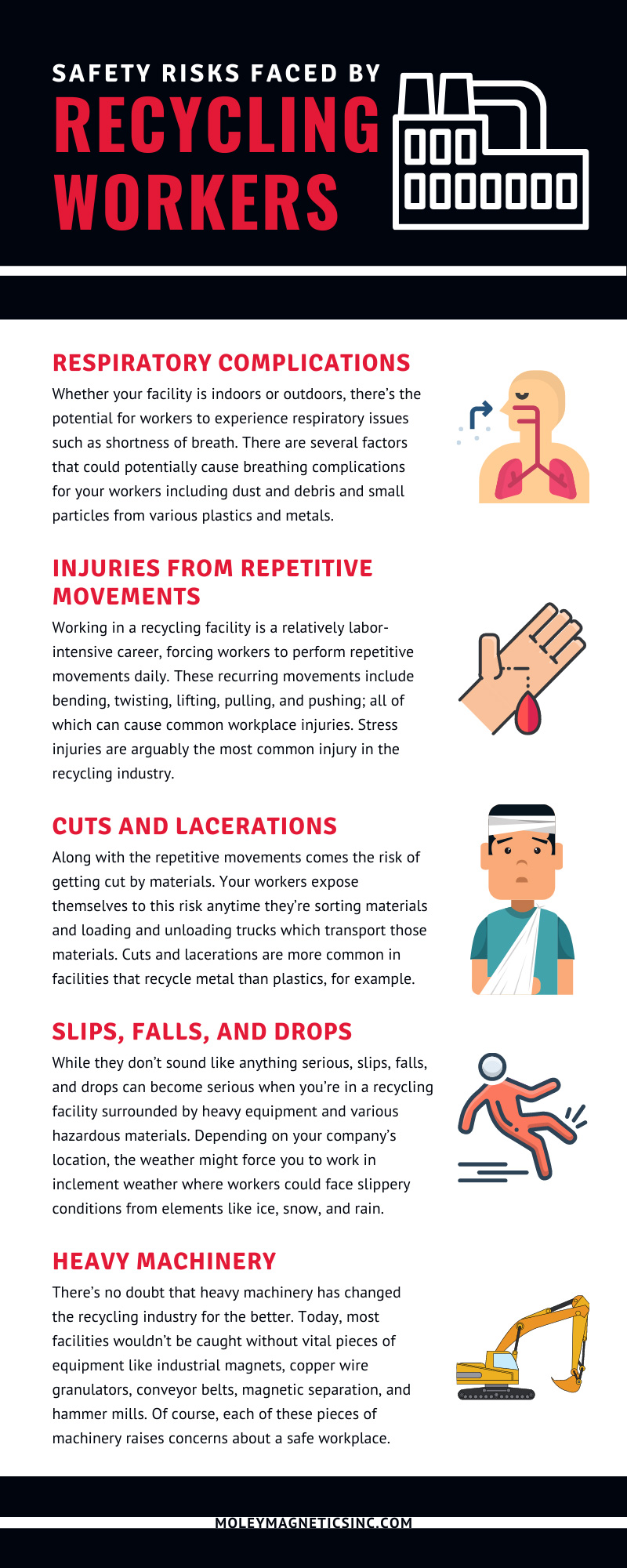

Respiratory complications

Whether your facility is indoors or outdoors, there’s the potential for workers to experience respiratory issues such as shortness of breath. There are several factors that could potentially cause breathing complications for your workers including dust and debris and small particles from various plastics and metals. Additionally, many recycling facilities handle various chemicals and toxic materials such as oil, solvents, batteries, and even radioactive materials. If a worker experiences any sort of respiratory complications, they should seek medical attention immediately because it could quickly turn into pneumonia or bronchitis. If the worker doesn’t report the illness, they’re likely contagious and getting others sick in the meantime.

Injuries from repetitive movements

Working in a recycling facility is a relatively labor-intensive career, forcing workers to perform repetitive movements daily. These recurring movements include bending, twisting, lifting, pulling, and pushing; all of which can cause common workplace injuries. Stress injuries are arguably the most common injury in the recycling industry. Stress injuries can affect different parts of the body including the back, arms, shoulders, elbows, hands, fingers, legs, knees, and feet. One of the best ways to prevent repetitive stress injuries is to encourage good posture for those lifting and sorting materials.

Cuts and lacerations

Along with the repetitive movements comes the risk of getting cut by materials. Your workers expose themselves to this risk anytime they’re sorting materials and loading and unloading trucks which transport those materials. Cuts and lacerations are more common in facilities that recycle metal than plastics, for example. The reason is quite simple, as sheet metal can be very sharp at times, and other metal objects can have metal shards on them. Keep in mind the metal was disposed of for a reason. While many recycling facilities use industrial magnets to load and unload ferrous materials, some facilities still have their workers performing this task by hand. If your facility is the latter, your first responsibility is to ensure your workers are always wearing safety gloves. Your next task is investing in a magnet because your workers will be safer, and your company will be much more efficient.

Slips, falls, and drops

While they don’t sound like anything serious, slips, falls, and drops can become serious when you’re in a recycling facility surrounded by heavy equipment and various hazardous materials. Depending on your company’s location, the weather might force you to work in inclement weather where workers could face slippery conditions from elements like ice, snow, and rain. Additionally, workers could potentially fall or trip when working near heavy equipment on uneven surfaces (if outside), or even if you simply have a few clumsy employees.

Lastly, many recycling facilities use heavy machinery to lift and move items overhead because it’s far more efficient than having workers carry materials. However, hoisting materials overhead causes several safety risks, most notably drops. Ideally, your recycling facility or yard will have a designated area for hoisting materials where no one but the machine operator can go. It’s always best to keep workers as far away from danger as you can, but sometimes that’s simply not possible. Maybe your facility doesn’t have the space for a designated area. Alternatively, your crew might need the materials near them and lifting and lowering materials overhead is the only way to do that. There are general guidelines for all lifting operations, such as inspecting your hardware to ensure it’s capable of holding the weight of the material. Additionally, workers should always stay clear of the area when they’re moving the materials, and everyone should be wearing proper PPE including hard hats.

Heavy machinery

There’s no doubt that heavy machinery has changed the recycling industry for the better. Today, most facilities wouldn’t be caught without vital pieces of equipment like industrial magnets, copper wire granulators, conveyor belts, magnetic separation, and hammer mills. Of course, each of these pieces of machinery raises concerns about a safe workplace. Manufacturers that make these machines are held to extremely high standards to ensure their machines are safe to operate, and they are. So why are there so many injuries caused by machines? A lot of the time, injuries happen due to a user error caused by a lack of training. As the facility manager, you need to develop a comprehensive training program for workers. Without your people, your company wouldn’t exist, and if your people continue getting hurt, you need to go back to the drawing board and find out why. Most of the time, the answer is improper training. Even if you feel like you’ve been over policies and procedures about operating machinery before, go over it again. You’ll never overtrain someone, but you can certainly undertrain them.

Whether your facility handles sheet metal, plastics, compostable items, or general household recyclables, each facility has its own unique risks. We highlighted the major safety risks faced by recycling workers in all recycling facilities. Just know that your workers could be more (or less) susceptible to the risks depending on the materials your facility handles. There are three ways that are guaranteed to significantly reduce (or eradicate) any and all safety hazards. First and foremost, you need to offer regular training for all employees. Additionally, you should invest in quality equipment that will operate properly and reliably. Lastly, OSHA is a government agency grounded in keeping workplaces safe for a reason. Follow OSHA’s guidelines and your workers will be safe, and the company will avoid fines and potentially being shut down.

Finally, every recycling facility needs heavy equipment in order to be successful and profitable. If your facility is looking for an excavator magnet, waste handling grapples, conveyor belt, hammer mill, vertical press, or concrete pulverizers, look no further than Moley Magnetics. Our family-owned business takes pride in offering only the highest-quality products for all our customers. With our products, you’ll be able to take your recycling services from average to outstanding. Our customer service team is ready to help you with a price request, so call us today!