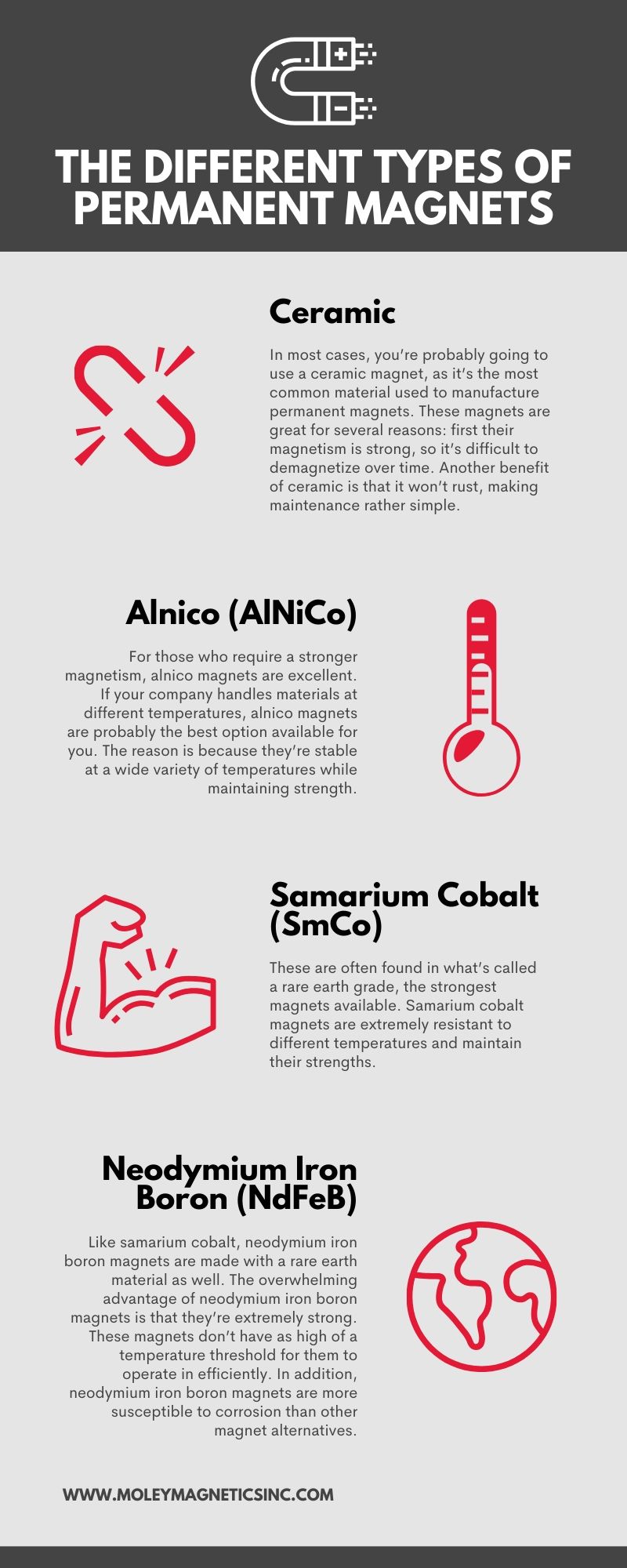

The Different Types of Permanent Magnets

Since the 1950s, permanent magnets have proven to be an essential piece of equipment in most industries. Between their versatility and ease of use, many companies find themselves investing in permanent magnets to increase efficiency, without having to do much training, if any. However, companies must decide which type of permanent magnet they want, and most important, the material used to manufacture the magnet. Continue reading to learn the different types of permanent magnets, which one is right for you, and why your company needs a permanent magnet.

First, what are permanent magnets?

Before getting into the types, we first need to understand what permanent magnets are and how they’re different. First, permanent magnets come from ferromagnetic materials (more on that later), which allow for a consistent magnetic magnetism––hence the term permanent. Unlike electromagnets and other alternatives, you don’t have to worry about having an external power source, such as a battery or generator with permanent magnets.

The different materials and which one is right for you

Permanent magnets are manufactured with four main types of materials: ceramic, alnico, samarium cobalt, and neodymium iron boron. Below we’ll discuss the advantages and disadvantages of each material and help you decide which is best for your needs.

Ceramic

In most cases, you’re probably going to use a ceramic magnet, as it’s the most common material used to manufacture permanent magnets. Ceramic, or sometimes referred to as ferrite, magnets are made with several elements, such as sintered iron oxide and barium. These magnets are great for several reasons: first their magnetism is strong, so it’s difficult to demagnetize over time. Another benefit of ceramic is that it won’t rust, making maintenance rather simple. Alternatively, ceramic magnets can be extremely hard, making them fragile especially when dropped.

Alnico (AlNiCo)

For those who require a stronger magnetism, alnico magnets are excellent. Manufacturers primarily use aluminum, nickel, and cobalt to build alnico magnets. If your company handles materials at different temperatures, alnico magnets are probably the best option available for you. The reason is because they’re stable at a wide variety of temperatures while maintaining strength. There are two common types of alnico magnets: cast and sintered. Cast alinco are the most common because there are several different grades, including options that are capable of maintaining most of their strength in temperatures over 1000 degrees Fahrenheit. Alternatively, sintered alnico magnets are typically weaker in terms of their magnetism, but they’re better for mechanical uses.

Samarium Cobalt (SmCo)

Manufacturers build these magnets using samarium and cobalt and a sintering method. These are often found in what’s called a rare earth grade, the strongest magnets available. Samarium cobalt magnets are extremely resistant to different temperatures and maintain their strengths. Many companies have samarium cobalt magnets for magnetic separation in several industries, such as pharmaceuticals, automotive, aerospace, manufacturing, and more. In other words, samarium cobalt magnets are one of the strongest and most versatile industrial magnets available on the market today.

Neodymium Iron Boron (NdFeB)

Like samarium cobalt, neodymium iron boron magnets are made with a rare earth material as well. The overwhelming advantage of neodymium iron boron magnets is that they’re extremely strong. Additionally, they serve several applications which is why they’re often found in places like magnetic separation setups, wind turbines, motors, and so on. However, there are two factors to keep in mind when considering neodymium iron boron magnets: temperature and corrosion resistance. These magnets don’t have as high of a temperature threshold for them to operate in efficiently. In addition, neodymium iron boron magnets are more susceptible to corrosion than other magnet alternatives.

Why you need permanent magnets

Every company invests in industrial-grade magnets for different reasons. Some need high-quality magnets for magnetic separation, while others need magnets for construction applications, such as skid steer attachments. However, many companies could benefit from investing in permanent magnets for three main reasons: maintenance, cost effectiveness, and ease of use. Though some of you may not be able to completely get away from generators and power sources, permanent magnets don’t require a power source. Having an external power source means you have more to maintain in addition to the magnet and other operations. If you’re able to reduce your power source usage, you’ll be able to save your company some money on maintenance and repairs over time. Even if you maintain your equipment well consistently, your equipment still needs routine maintenance. Think of it like an oil change for your car: even if you keep up on regular maintenance, you still need an oil change every few months. Lastly, since permanent magnets have a consistent magnetism, you can save money on both training and electrical costs.

There are plenty of magnets available on the market, and you have to do your fair share of research to identify which magnet is best for your company. However, permanent magnets are one of the most versatile options, and if you find out what your needs are during your research, you really can’t go wrong. That said, there are two factors you need to consider when deciding which magnet to purchase. First, you need to know the different types of permanent magnets, which we helped you with. Second, you need to consider the quality and longevity of the product. We know it’s easy to choose the magnet with the best price tag. However, keep in mind that going with the cheapest option isn’t always the best use of your money. In fact, the cheapest is cheap for a reason, and that reason is usually because the manufacturer used low-quality materials. That said, you’ll probably spend equal or more money on repairs than you would’ve if you just bought the quality product in the first place.

Here at Moley Magnetics, we believe your company and workers deserve to have reliable and high-quality products to work. That’s why our family business takes pride in helping others do great work with our industrial magnets. We serve a wide array of industries from scrap yards to truck builders to railroads. Regardless of which industry you’re in, we likely have something that’ll fit your needs. Whether you’re looking for a scrap yard magnet, railroad attachments, or more, we only offer the highest-quality products. Contact us today for more information.