Understanding How Drum Magnets Work

Whether you work in scrap metal, food and beverage manufacturing, mining, or pharmaceuticals, you’re probably using some sort of magnetic separation to ensure top quality. While there are several variations of magnets used, drum magnets are among the most common. Although drum magnets can appear complex to some, they’re not as complicated as they seem. If you’d like to develop an understanding of how drum magnets work, we’ve got you covered in the following guide. Read on to learn more.

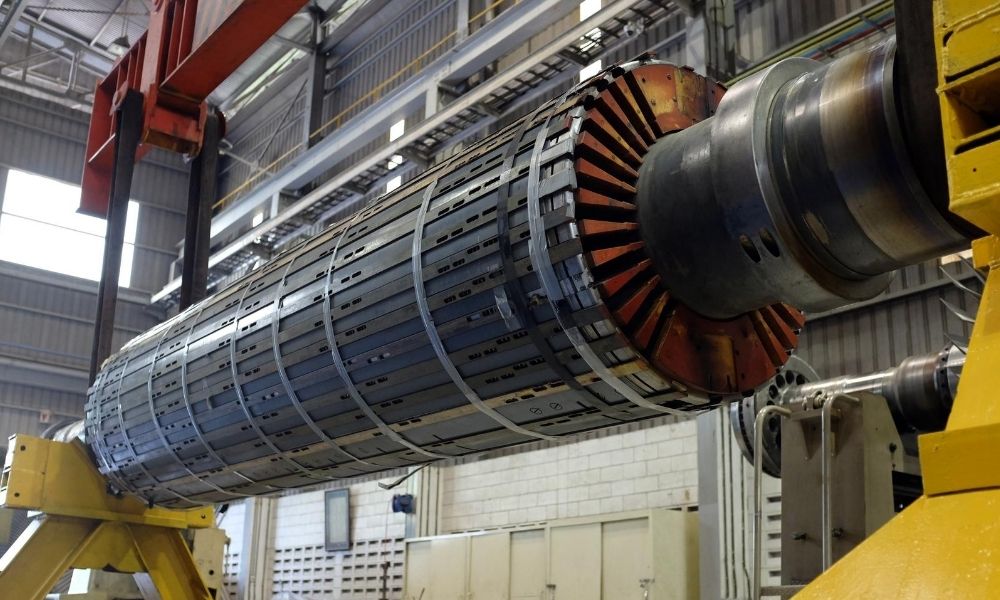

The magnet and its housing

Drum magnets are self-cleaning and cylindrical in shape, with a magnetic core that rotates in order to separate ferrous from non-ferrous materials efficiently. Drum magnets come in a variety of dimensions to fulfill the needs of users, but in addition to the magnet is its housing. Some drum magnets remain exposed, but many are enclosed to ensure peak performance and protect the magnet from external factors. The magnet’s casing can vary depending on how you’re feeding materials to the magnet.

The different feed methods

When installing a drum magnet, you must identify the type of feeder you plan to use––most facilities use a conveyor belt. From there you can decide which feed method you’re going to use. There are three common feed methods: up-and-over, down-and-under, and top feed. Up-and-over feed attracts the ferrous materials up-and-over the drum, while non-ferrous materials pass underneath and go into a separate container. The down-and-under method carries ferrous materials under the drum and places them on the opposite side. Finally, as part of the top feed method, magnetic materials descend from above the drum which allows weaker material to go through the separation process.

Each separation method has its own advantages and disadvantages depending on the material’s size, weight, and magnetic properties. Drum magnets are one of the most common ways to separate magnetic particles from flow streams because they’re so efficient and user-friendly. Much like other industrial equipment investments, your drum magnet will only be as good as its quality.

To ensure top quality, you should only work with a dependable magnetics manufacturer like Moley Magnetics. We make our products with only the highest-quality materials available because we know our customers need reliable equipment. Moley Magnetics is a family-owned business, and we take pride in that. When you work with us, you can rest assured that you’re in good hands. We’re your one-stop-shop for all things like excavator magnets and electric motors, including service and repairs. If you’re ready to invest in your equipment, contact us today. Our family will be sure to take care of you.