How To Start Your Own Scrap Metal Recycling Business

As environmental awareness increases, so does the need for more metal recycling companies. After all, various industries—automotive, appliance, construction, etc.— produce scrap metal, so we need someone to recycle it. Get the advice you need in this article on how to start your own scrap metal recycling business in just a few simple steps.

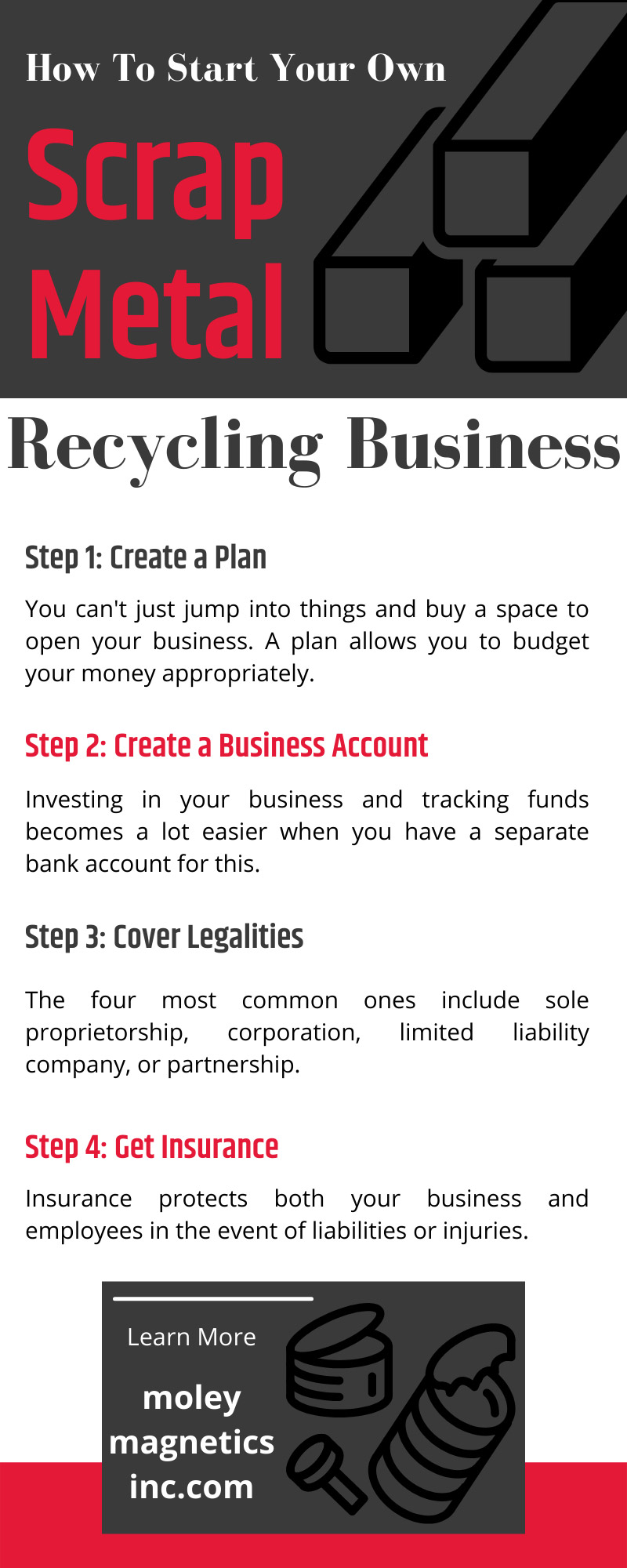

Step 1: Create a Plan

You can’t just jump into things and buy a space to open your business. A plan allows you to budget your money appropriately. Consider the following:

- Decide on a target market: What industries do you most want to sell to?

- What amount you’ll pay sellers: What will you pay in exchange for scrap metal?

- What you charge: How much will ingots cost once you resell the scrap?

- Business name: How will your business name help you stand out?

- Equipment: What kind of excavators, material handlers, excavator scrap shears, scrap yard magnets or waste handling grapples are needed?

Owning a business isn’t easy and requires a lot of planning and understanding of your industry. Investigate the ongoing cost for various metal types, so you pay and charge partnering businesses appropriately.

Stick To a Budget

One of the first things you should do as you plan is to create a budget. How much money will you initially invest into the business? Your starting budget should cover the cost of land, machinery, transportation, employee pay, and more. Avoid making those big-ticket purchases right away if you don’t have to, and focus on purchasing the necessities instead.

Remember Ongoing Expenses

You should also note those ongoing expenses like taxes, payroll, and insurance as you create your budget. These unavoidable expenses can build up in a hurry.

Understanding Your Target Market

When it comes to a target market, you’ll have to decide what types of metal you’ll scrap as this will impact the types of businesses you will work with. For example, if you only scrap iron-based material, you can only sell it to those who will use it.

Additionally, the type of metal you decide to scrap impacts how much you’ll sell it for—you’ll make more money selling copper than you would aluminum, but it may be harder to obtain in your area.

Naming Your Business

Naming your business is among the most important parts of ownership, so take time to do so. You’ll want something easy to remember but also fresh in the customer’s mind. Once you settle on a name, you’ll need to ensure no other business already has claims to it, and if not, register it for yourself.

Step 2: Create a Business Account

Investing in your business and tracking funds becomes a lot easier when you have a separate bank account for this. This way, you can also invest in new assets and track other expenses you make without worrying about it getting intermixed with your personal spending.

Pro Tip

When you open a business account, get a credit card for the company. This way, you can charge expenses such as tools and machinery to a single account that is easy to track and helps improve your company’s credit history.

Step 3: Cover Legalities

When the time comes to register your business, you’ll have to decide what type of business structure you’d like to implement. The four most common ones include sole proprietorship, corporation, limited liability company, or partnership.

After settling on a business structure, you’ll also have to register for taxes—you’ll do this after picking a business structure since that impacts how you’ll pay. This is also where having a business account at the bank comes into play. When the time comes to file your taxes, it’s much easier to note your expenses and determine what you can write off when business and personal money remain separated.

Obtaining Licenses

Finally, you’ll also need to obtain the required permits and licenses so you can open a shop, such as a metal recycling license and a Certificate of Occupancy.

Since you’ll buy and resell metal, you’ll need the appropriate license to do so legally. Almost every state requires businesses in your industry have a metal recycling license to ensure you follow legal measures throughout the life of your business. If you don’t know what licenses you need, contact your city clerk’s office for further information.

Step 4: Get Insurance

You’ll need insurance for both your business and employees, so you’ll have to decide on which policies you prefer. You may find some that are out of your price range, so keep your budget in mind as you look around for what’s best. Insurance protects both your business and employees in the event of liabilities or injuries.

Step 5: Purchase the Essential Tools

One of the most important parts of knowing how to start your own scrap metal recycling business is gathering the necessary tools. Before you begin collecting scrap, you should purchase the appropriate tools and equipment, so you don’t wind up with piles of scrap metal and no way to recycle it. You’ll need:

- Company vehicles to transport scrap

- Storage facilities for scrap and ingots

- Toolbox with wrenches, screwdrivers, etc.

- Power drills and drill bits to disassemble materials

- Wire granulators to separate wire from casing

- Scrap yard magnets to separate ferrous from non-ferrous metals

In addition to this, employees should have the protective gear so they can safely handle all metals throughout the recycling process. By having all of this before officially opening up shop, you’ll be completely prepared, and your team of workers can complete tasks more efficiently.

Pro Tip

Buy your scrap yard magnet, waste handling grapple or excavator scrap shear and other machinery for recycling from Moley Magnetics. As industry leaders, see we’ve got all the high-powered equipment you need to make your business a thriving success!

Step 6: Begin Collecting Scrap

Once you’ve covered all the essentials, it’s finally time to open your doors and begin collecting scrap. Consider marketing yourself online or contacting local businesses working in the metal industry to see if they have metal to recycle.

The more you advertise your business, the more likely you are to attract new customers, and as you work with these companies, you can build relationships. As you establish these relationships, ask for references to further expand your services throughout the community.

3 Mistakes To Avoid When Sorting Your Scrap Metal

Recycling scrap metal isn’t as simple as saying goodbye and tossing it in the recycling bin. First, you’ll have to sort out the various metal types to ease the process. As you do this, it’s best to note the common mistakes to avoid when sorting your scrap metal. By keeping yourself and your employees aware, scrapping metals becomes much more manageable.

Failing To Understand the Values of Metals

One of the most important things to note is that some metals are more valuable than others. While this can depend on supply and demand economics, specific materials like copper are always highly valued. Having a thorough understanding of the values of various scrap metals sets your business up for success.

Not Separating Your Metals

Forgetting to separate metals is another common mistake to avoid when sorting your scrap metal that could mean making less money when you take it to the scrap yard. For example, copper and non-ferrous metals sell at a higher price. By taking time to sort this out, you make it easier to sell your scrap for a fair amount of money.

Use an industrial magnet or a Moley Magnetics 2 in 1 sorting claw magnet to sort out your metals since this allows you to separate magnetic material from non-magnetic. By separating these, you can sell each for the individual price. If a specific metal has a lower value than expected, hold onto it until prices increase. At Moley Magnetics, you can purchase a scrap yard magnet to keep sorting simple.

Forgetting Scrap Yard Requirements

When it comes to sorting your scrap metal, one of the first things you should do is investigate the scrap yard’s requirements for metal types plus other rules. Next, aim to establish a relationship with a single scrap metal recycling center, so you always understand their recycling rules.

This could differ from company to company, and the best way to get clarification is by contacting the business and asking about what rules they have. For example, some companies may specialize in recycling a specific type of scrap, but others may not be so picky.

Pro Tip

As you establish a relationship with a scrap yard, ensure the business is reputable. A trustworthy recycling company will give you a fair price for your scrap, while also correctly recycling it so others can eventually reuse it.

Make separating your metals easy by purchasing high-powered industrial magnets from Moley Magnetics. Once you’ve expertly separated all your materials, sell them for the best prices. By tracking those profits, you make it simple to reinvest in your business with updated tools and machinery that make tasks easier.

Eco-Friendly Material: What Makes Stainless Steel Sustainable

Going green has become the key to success for many companies, both financially and in terms of boosting their reputation. By reusing resources, we conserve both natural and unnatural resources, which can improve overall environmental awareness. But are some resources better to use than others? The fast answer is yes.

What Determines the Price of Scrap Metal?

Selling scrap metal is an easy way for many industrial companies to make money. Construction, food packaging, and automotive industries are just some of the many business types that often have scraps left over after finishing a job. The question is, what determines the price of scrap metal? Discover what factors influence these prices, plus several additional reasons you need to start selling your scrap material.

Industries That Can Benefit From Recycling Their Scrap Metal

Recycling is an important factor when it comes to creating a healthy environment. While some businesses reduce their eco-footprint by installing low-energy lighting and other fixtures, many industrial companies recycle scrap metal. Check out this list of industries that can benefit from recycling their scrap metal.

Why You Should Recycle Scrap Metal From Your Demolition Site

One company’s impact on the environment can affect everyone living in the community. So its actions have consequences. For example, teams of workers end up with piles of unneeded materials during demolition that contribute to waste. However, it’s possible to reuse some of this. Investigate why you should recycle scrap metal from your demolition site to keep the planet green.

Disposing of Metal on Your Construction Site

No builder likes to let materials go to waste. But in the process of cutting, shaping, and working with your materials, you still may find that you have a few leftovers—and that’s not even counting power tools. Leftover scrap metal is heavy, unwieldy, and takes up valuable storage space, and taking what’s left to the dumpster means a total loss when it comes to expenses. Fortunately, with conservation-minded strategies for disposing of metal on your construction site, no material ever truly goes to waste. You may be getting leftover metal off the premises, but rest assured it’ll end up being put to good use—even including those worn-out tools.

Obsolete vs. Prompt Scrap: The Differences

Love may make the world go round, but recycling metal is what keeps the manufacturing world turning. Mining is hard and energy-intensive work, so whenever you can reduce the demand for new metal, it’s a boon to the planet and your bottom line. But recycling metal isn’t as simple as filling a bin with old cans once a week. The salvage industry relies not only on disused consumer products but on access to industrial byproducts that may never enter the layman’s mind. Read on to explore obsolete vs. prompt scrap and their differences.

Ferrous vs. Non-Ferrous Scrap Metals

The scrap metal has seen exponential growth over the course of centuries; in fact, it’s a $29.9 billion industry as of 2020. In addition to the growing industry, there are millions of people the industry employs year over year. Included in those millions of people are CEOs, upper-management, supervisors, and every other employee. Regardless of which employee you are, you must have a solid understanding of the different materials you handle. In the scrap metal industry specifically, you’ll handle a lot of ferrous and non-ferrous materials. Whether you’re a line worker in a scrap metal facility or you own the company, you must understand ferrous vs. non-ferrous scrap metals. If you’d like to learn more about ferrous and non-ferrous metals and how they can affect your scrap metal business, we’ve got you covered; read on to learn more.

How to Maximize Scrap Metal Profits

Businesses and individuals alike often forget about all the metal they have that they’re not using, which they could scrap for extra money. Whether you’re a scrap metal business, or simply an individual looking to get the most for your metal, you deserve top dollar. Keep reading to learn how to maximize scrap metal profits.

Call the scrapyard beforehand

Though most scrapyards won’t turn away business, sometimes they have to if there’s an influx of people trying to sell their metal, so it’s a good idea to call before you load your vehicle up. You also should call beforehand to get the scrapyard’s prices over the phone. While the price of scrap metal is largely influenced by market and index prices, that doesn’t mean that each scrapyard is following that trend.