Common Issues With Submersible Pumps

Companies from a wide array of industries use submersible pumps regularly. Municipalities will use submersible pumps to drain a local pond or use it as a filter. A city may also use them for dirtier jobs such as sewage draining. Alternatively, construction companies also use submersible pumps if their job site has standing water or other liquids. Disaster relief organizations such as the American Red Cross may also use submersible pumps in the event of flooding. Make no mistake—the applications of submersible pumps go far beyond the examples just mentioned. But like anything else, submersible pumps can have some issues. If you’d like to learn what the common issues with submersible pumps are, we’ve got you covered in our comprehensive guide below.

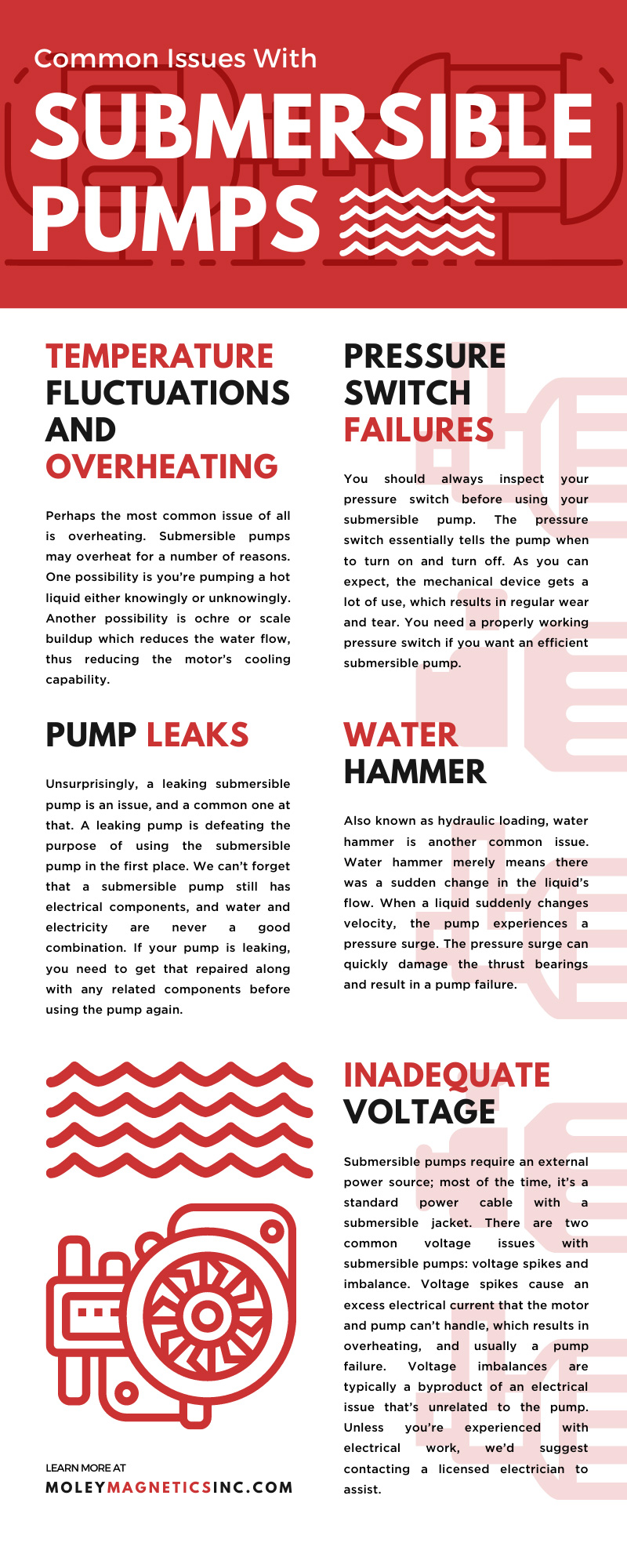

Temperature Fluctuations and Overheating

Perhaps the most common issue of all is overheating. Submersible pumps may overheat for a number of reasons. One possibility is you’re pumping a hot liquid either knowingly or unknowingly. Another possibility is ochre or scale buildup which reduces the water flow, thus reducing the motor’s cooling capability. For those of you who don’t know, a submersible pump virtually cools itself by operating. As the water (or other liquid) flows through the pump, that liquid acts as a coolant. If the pump’s “coolant” is significantly reduced, it’s more likely that the motor will start and stop frequently, resulting in the motor overheating.

Pumping too hot of a liquid may result in damaging the internal components of the pump and motor. Most submersible pumps have bearings that provide a thin film of water between the different surfaces in the pump; you could think of it as a lubricant. If the liquid you’re pumping is too hot, the components may reach a boiling point which can diminish that small film. When the small film deteriorates from the hot liquid, the internal components can come in contact which produces heat quickly. While this all might sound like hot water is the problem, it’s not. The problem is likely the pump itself, as not all pumps are designed for hot liquids. Before pumping hot liquids, you should always check your pump’s working temperature range to ensure that it’s capable of pumping the liquid.

Water Hammer

Also known as hydraulic loading, water hammer is another common issue. Water hammer merely means there was a sudden change in the liquid’s flow. When a liquid suddenly changes velocity, the pump experiences a pressure surge. The pressure surge can quickly damage the thrust bearings and result in a pump failure. There are two primary ways to prevent hydraulic loading. First, you could install check valves which prevent liquid backflow. In other words, check valves allow the liquid to pass going forward but closes if the liquid reverses. The other prevention method is like any other motor or pump—regular maintenance. You should frequently inspect the pump’s components and look for signs of corrosion, as corroded components can exacerbate a failure.

Inadequate Voltage

Submersible pumps require an external power source; most of the time, it’s a standard power cable with a submersible jacket. There are two common voltage issues with submersible pumps: voltage spikes and imbalance. Voltage spikes are most common during severe storms because lightning strikes can cause a sudden jump in voltage. In most cases, the spike causes an excess electrical current that the motor and pump can’t handle, which results in overheating, and usually a pump failure. If you can avoid using your pump during storms, you should—otherwise you could invest in a quality surge protector. On the other hand, we have a voltage imbalance. Typically, a disproportionate supply of voltage is merely a byproduct of an electrical issue that’s unrelated to the pump. Unless you’re experienced with electrical work, we’d suggest contacting a licensed electrician to assist.

Pressure Switch Failures

You should always inspect your pressure switch before using your submersible pump. The pressure switch essentially tells the pump when to turn on and turn off. As you can expect, the mechanical device gets a lot of use, which results in regular wear and tear. You need a properly working pressure switch if you want an efficient submersible pump. Far too many pump owners try to repair their pressure switch, which is a mistake because you can’t adequately repair them once they’ve broken down. Instead, it’s better to replace the pressure switch when it goes bad, as they’re relatively inexpensive anyway.

Pump Leaks

Unsurprisingly, a leaking submersible pump is an issue, and a common one at that. A leaking pump is defeating the purpose of using the submersible pump in the first place. The pump could be leaking for a number of reasons, many of which are byproducts of the issues previously mentioned in this guide. For instance, a pump may leak if the pressure switch fails or if the small film deteriorates from overheating and damages the bearings. Aside from the fact that a leaking pump is inefficient, it also raises safety concerns. We can’t forget that a submersible pump still has electrical components, and water and electricity are never a good combination. If your pump is leaking, you need to get that repaired along with any related components before using the pump again.

A lot of people think they can repair pumps themselves by following a blog or watching a YouTube video. While you might get a temporary fix by attempting to repair the pump yourself, it’s not going to last. Additionally, you could cause further damage if you’re not repairing the pump correctly with quality components. Every company that uses pumps and motors frequently needs reputable repair service on their side to ensure their equipment is always in optimal working condition. Without a trustworthy repair service, you’re only going to waste your time and money and potentially damage your equipment.

If your company is experiencing the common issues with submersible pumps, you need to form a partnership with Moley Magnetics. Our team consists of seasoned professionals who offer a wide array of pump repair services. When you work with the experts at Moley Magnetics, you can count on integrity and honesty. If we find that your pump is beyond repair, we’ll tell you. Luckily, we also supply new pumps, so you won’t have to go searching further for a replacement pump. In other words, we’re your company’s one-stop-shop for all things magnets, heavy equipment attachments, pumps, and motors. Contact our team today if you have any questions or if you’d like to request pricing.