Electric motors have become a standard piece of equipment for many industries in recent years. These industries include construction, manufacturing, scrap yards, automotive, and more. Electric motors have become increasingly efficient over the years and have helped all these industries perform daily operations in a timely and reliable manner. However, many organizations make the mistake of neglecting maintenance, and then they can’t understand why their motors aren’t performing like they used to. In fact, without proper maintenance, some motors may be beyond repair and need a replacement. This not only increases a company’s expenses but will also increase their downtime and decrease productivity. The good news is all of these problems are preventable. Just continue reading our top tips for maintaining electric motors to learn how.

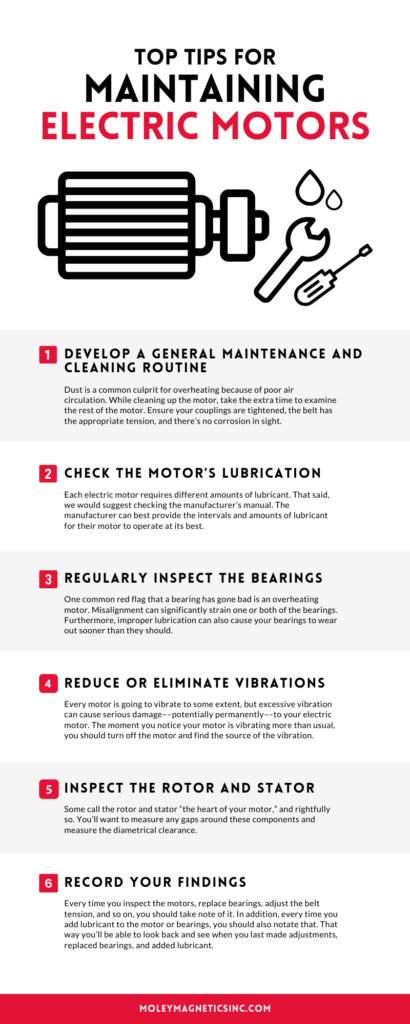

Develop a general maintenance and cleaning routine

Every company should have a cleaning routine in place if they don’t already. Simply keeping your motor clean can significantly improve its performance and lifespan. Your motor should never have excessive grease, dust, or other debris on or in any of its parts. Dust is a common culprit for overheating because of poor air circulation. While cleaning up the motor, take the extra time to examine the rest of the motor. Ensure your couplings are tightened, the belt has the appropriate tension, and there’s no corrosion in sight.

Check the motor’s lubrication

Believe it or not, it’s absolutely possible to overlubricate a motor, which can lead to internal problems. However, your motor needs lubricant to operate at peak performance level. Each electric motor requires different amounts of lubricant. That said, we would suggest checking the manufacturer’s manual. The manufacturer can best provide the intervals and amounts of lubricant for their motor to operate at its best. Lubricating the motor too early or too late can result in premature wear and tear. Additionally, manufacturers typically recommend a specific lubricant that’s designed for their motor. It’s important to use the suggested lubricant; otherwise, you could risk voiding a manufacturer’s warranty.

Regularly inspect the bearings

The motor’s bearings experience some of the most wear and tear, so it’s only natural to expect them to cause issues from time to time. Much of the preventative measures you can take we’ve already discussed, such as general maintenance and keeping the motor clean. However, bearings can go bad for several other reasons. To avoid bearings wearing out earlier than they should, you first must assure the motor is aligned properly. Misalignment can significantly strain one or both of the bearings. Furthermore, improper lubrication can also cause your bearings to wear out sooner than they should. One common red flag that a bearing has gone bad is an overheating motor. Each motor has a different working temperature, so it’s important to read the manufacturer’s manual to find your motor’s recommended temperature. All that said, there is one factor to consider when inspecting your bearings and motor as a whole––and that’s vibration. In most cases, you merely need new bearings, which is normal as they’re essentially consumables since they wear out over time. However, to extend the life of your bearings, sometimes you need to change to a different type of bearing. Many of you probably have shielded bearings when you could be using open or sealed bearings. As always, it’s best to find out if the manufacturer of your motor suggests such bearings prior to installation.

Reduce or eliminate vibrations

Every motor is going to vibrate to some extent, but excessive vibration can cause serious damage––potentially permanently––to your electric motor. The moment you notice your motor is vibrating more than usual, you should turn off the motor and find the source of the vibration. The source is usually a mechanical issue such as misalignment, a worn-out bearing, or belt tension that is too high. You could remove the belt and then do a test run to see if the motor is still vibrating. On the other hand, the cause of the problem could be your power source, which is a more serious concern. The bottom line is, in order to avoid excessive vibrations, you need to ensure proper alignment and that the bearings are in good condition.

Inspect the rotor and stator

Some call the rotor and stator “the heart of your motor,” and rightfully so. The rotor and stator are the essential components to the motor; if you take one of them away, you won’t have an operating motor. You’ll want to measure any gaps around these components and measure the diametrical clearance. The diametrical clearance measures free movement in the inner and outer race mounts. Your clearance can vary depending on your motor and the bearings.

Record your findings

You can’t monitor the longevity and wear and tear of your motors if you’re not recording the information. Every time you inspect the motors, replace bearings, adjust the belt tension, and so on, you should take note of it. In addition, every time you add lubricant to the motor or bearings, you should also notate that. That way you’ll be able to look back and see when you last made adjustments, replaced bearings, and added lubricant. By keeping track of your general maintenance and cleaning schedules, you can hold yourself and your crew accountable. Furthermore, you can better anticipate upcoming expenses and maintenance and plan accordingly.

Your company relies on efficient electric motors for your daily operations. For some of you, that might mean industrial fans, and for others that means your industrial machinery. Regardless, your electric motors must work smoothly and reliably. To ensure your electric motor works properly––and arguably more important, lasts––you must have a regular maintenance schedule. With these top tips for maintaining electric motors, you should be well on your way to a long-lasting electric motor. And without regular maintenance, you may find you need a repair service.

Look no further than Moley Magnetics. Our business began as a motor repair shop in our garage. Today, we’re recognized as one of the top industrial magnet suppliers and electric motor repair servicers. Our family values hard work and high-quality products and services, and that’s why our customers prefer working with Moley Magnetics. Through our extensive experience, integrity, and value for quality work, we’ll get your motor up and running in no time. Contact us today for more information.