Types of Lifting Magnets for the Steel Mill Industry

Among the many industrial sectors of the American economy, the steel industry is both historically and currently one of its most important. The steel industry has built America in more ways than one. Mining the iron that we process into steel provided jobs in northern Minnesota and Michigan—the famous Iron Range. The industrial heart of the Midwest is dotted with “steel towns” that grew around their mills: Gary, Indiana; Youngstown, Ohio; and Dearborn, Michigan, where the steel crossed the street to the Ford Motor Company, to name but a few. Most notable of all is the Steel City itself, Pittsburgh, Pennsylvania, the home of US Steel and the football team with a name that pays tribute to the industry.

Though a lot has changed in the American iron and steel industry since it peaked in the years following World War II, reports of its demise have been greatly exaggerated. Though many of the sprawling mills that made company towns of their surroundings have since shut down, we continue producing great volumes of steel as the world’s third-largest producer. In fact, we produce more of it than ever not from virgin iron but from recycled scrap, keeping steel in circulation for years to come.

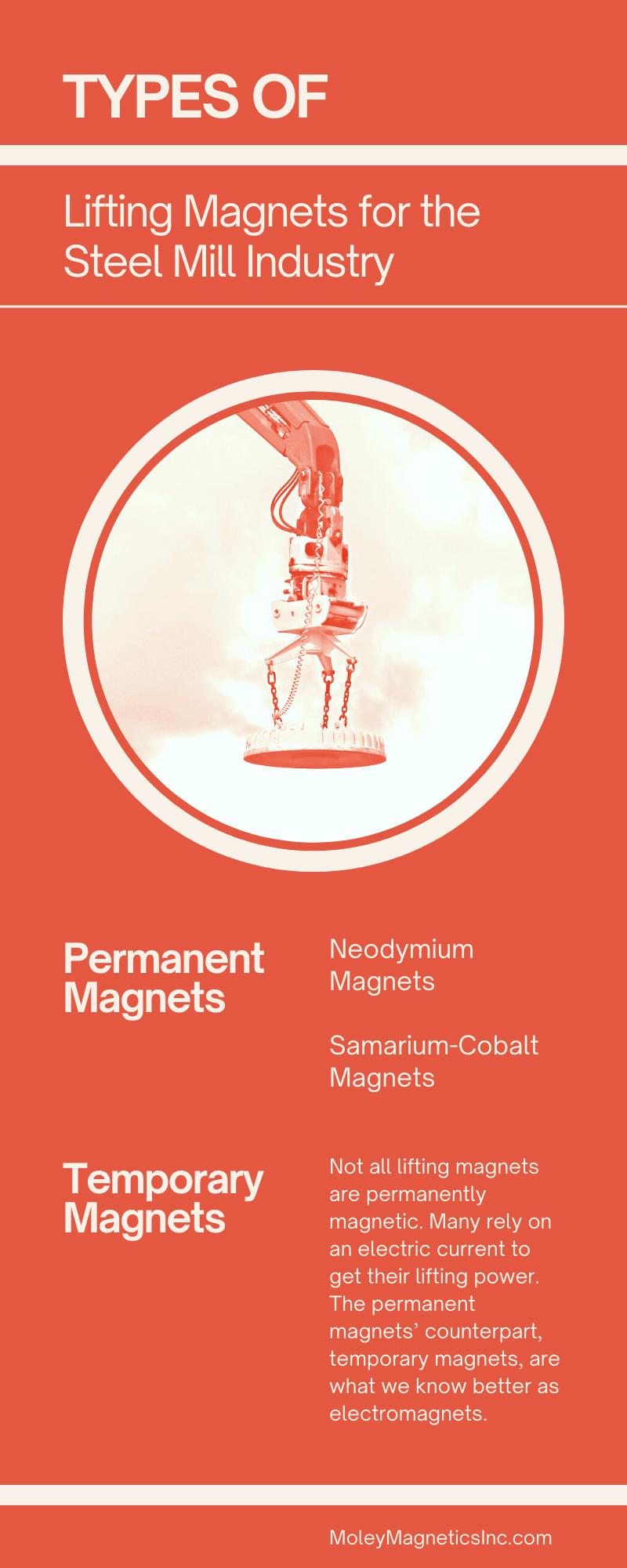

Even in today’s smaller and more streamlined facilities, 21st-century steel mills are sophisticated operations requiring brains and brawn, both human and technological. Steel, being a ferrous metal, or one derived from iron, is naturally magnetic. This enables the use of permanent and temporary magnets to aid in lifting and moving heavy or unwieldy pieces of steel that would be immovable by manpower alone. Among the many types of industrial magnets, lifting magnets have a special responsibility—more than any others, they can’t afford not to do their jobs and drop what they’re carrying. Magnets that manufacturers design specifically for lifting are some of the strongest ones on the market. To determine which models you can make the most use of at your lean but efficient modern steel mill, learn more about these types of lifting magnets for the steel mill industry.

Permanent Magnets

Simple but effective, permanent magnets rely on natural magnetism to do the job. You may be familiar with the permanent magnets you append to your refrigerator door, or the magnetism that occurs when the tips of two paper clips touch. A permanent lifting magnet is just like that—only orders of magnitude stronger. Rather than relying entirely on naturally magnetic iron or ferrite to create a magnetic field, manufacturers supplement iron with rare-earth elements to form powerful alloys that offer stronger fields than mere iron alone would allow.

Neodymium Magnets

Music enthusiasts should recognize the word “neodymium” from their headphones or earbuds. In modern sound systems, magnetism makes music, but at an industrial scale, with magnets far larger than the ones you would find in speakers, the power of a neodymium magnet is music to our ears. The name is a slight misnomer. A neodymium magnet is not pure elemental neodymium, but rather an alloy that combines it with iron and boron—Nd2Fe14B, to be chemically specific. Owing to their comparatively light construction, neodymium magnets turn up not only in audio applications but also in our computers’ hard drives, our smartphones, and the servomotors that power CNC mills and lathes. Larger models power the motors of electric and hybrid cars. At their largest, we deploy neodymium magnets for lifting heavy payloads such as steel, where the powerful permanent magnetic field of this alloy safely hoists ferrous metals.

Samarium-Cobalt Magnets

Using these magnets won’t make you a Good Samaritan, but they’ll help you get the job done. Another rare-earth permanent magnet, these models twin naturally magnetic cobalt—like nickel, an element that shares iron’s natural magnetism—with samarium, a rare-earth element that you’d find in the periodic table’s extended lanthanide series off to the side. SmCo5 magnets, as we know them in shorthand, boast a high resistance to demagnetization, making them lasting additions to facilities. Two other factors make SmCo5 lifting magnets particularly suited to the steel industry. First, while they may have steel casings, the magnets themselves lack the iron of other magnets, making them highly resistant to oxidation and corrosion and thus further lengthening their lifespans. Particularly pertinent to steel mills, samarium-cobalt magnets are amazingly resistant to great shifts in temperature. While high temperatures normally compromise the integrity of magnets, samarium-cobalt lifting magnets are equipped to withstand the heat.

Temporary Magnets

Not all lifting magnets are permanently magnetic. Many rely on an electric current to get their lifting power. The permanent magnets’ counterpart, temporary magnets, are what we know better as electromagnets. These make up the other half of the types of lifting magnets for the steel mill industry. While electromagnets can have a much higher lifting capacity than their permanent brethren, they also require a continuous current of electricity to do that lifting, which means taking power sources into consideration.

Powering Our Electromagnets

Lifting electromagnets mostly differ in their power sources. Many electromagnets rely on an incoming supply of alternating current and convert it to direct current, requiring an intermediate piece of equipment to make that conversion. When lifting tasks require more mobility than being tethered would allow, electromagnets hook up to portable generators, which provide direct current without the need for conversion. The most versatile electromagnets, however, feature battery power, enabling workers to do the heavy lifting required without worrying about the inherent variables of additional equipment or having to draw upon the power of a generator.

An Electromagnet That’s Sure To Steel Your Heart

An electromagnet with the high lifting capacity that you demand, along with the luxury of a battery-backed unfettered range of motion, truly gives your steel mill the best of both worlds. The Moley Mag II (ESB), the 24v scrap yard magnet from Moley Magnetics, features strength and flexibility in equal measure. Coming in various sizes for deftly handling various sizes of steel scrap, the magnet boasts an intuitive control system that practically makes it an extension of its operator’s own arms and hands. A 24-volt battery powers the electromagnet independently of any other power supplies. Best of all, the Moley Mag II comes at affordable price points—something today’s leaner and meaner mills can really appreciate. Start supplementing your mill with these magnets today. See our product on YouTube.