What You Should Know About Stepper Motors

Some jobs require you to take things one step at a time, and some jobs require that of the machinery as well. While many motors run simply as “on” or “off,” other motors for high-precision jobs work in discrete steps at the user’s command. We refer to these devices as stepper motors for their concentration on incremental work. Here’s a little of what you should know about stepper motors, from how they operate, to when they’re required, to when you’ll need to give them a closer look.

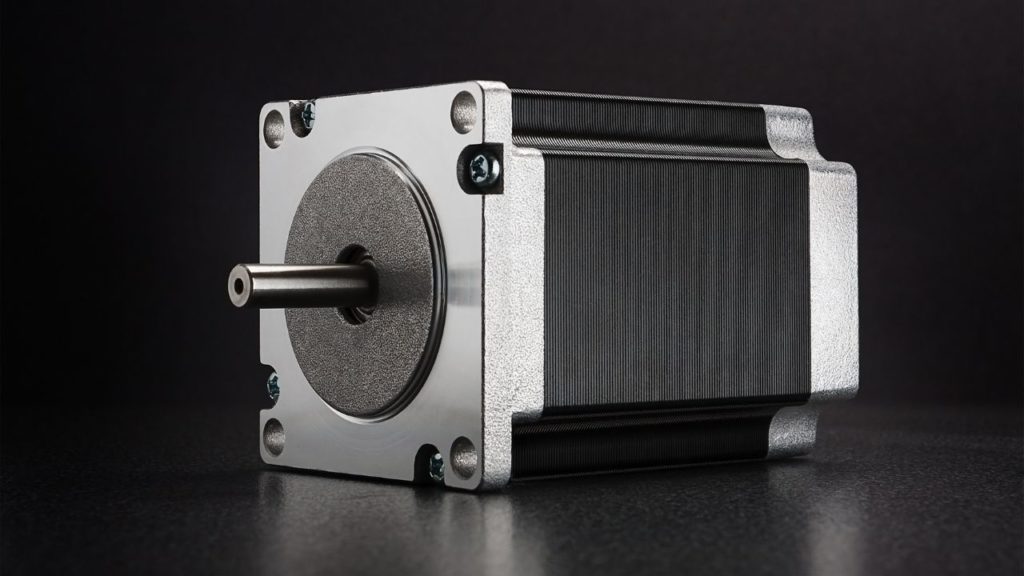

The Anatomy of a Stepper Motor

Stepper motors employ the principle of electromagnetism. Most stepper motors use permanent magnets at their core, with a magnetized rotor that is attracted to their stators, or housing. In a variable-reluctance stepper motor, the rotor is not a permanent magnet, but its stator is magnetized like a scrap yard magnet. This allows for higher speeds than its permanent-magnet counterpart. Hybrid motors synthesize these two approaches with two magnetized rotors of opposite polarity and an electromagnetic stator. Unlike motors that rely on alternating current, stepper motors run on direct current, the unidirectional flow of electricity. By running on DC, a motor can offer higher efficiency and precision than by running on AC.

Where We Use Them

Jobs that require hard work with a light touch make use of stepper motors. The high torque and precision of stepper motors is integral to automation and robotics, which often call for exact movements. Similarly, stepper motors power 3-D printers and CNC mills, which must make accurate and precise movements. Battery-powered toys often run on stepper motors as well. Even some hard disk drives employ stepper motors to reposition the heads, which read and write data on the disk. In short, any application that calls for meticulous control of speed and movement will likely involve the intricacies that a stepper motor provides.

What Can Go Wrong

One positive aspect of using stepper motors is that they don’t require regular on-site maintenance. Because steppers do not have brushes, they incur much less wear over time. However, that means that if a stepper motor should fail, it’s likely not the kind of problem you can fix yourself. Whether a magnet has lost its charge, debris has clogged the motor, or the wear and tear of regular usage have simply caught up with the components, this sort of repair isn’t the kind you should take on yourself, as inexperienced hands can permanently disable a stepper’s magnet. Fortunately, the magnetism experts at Moley Magnetics can handle your DC motor repair, protecting you from the costs of outright replacement.