Environmental and Economic Advantages of Recycling Copper

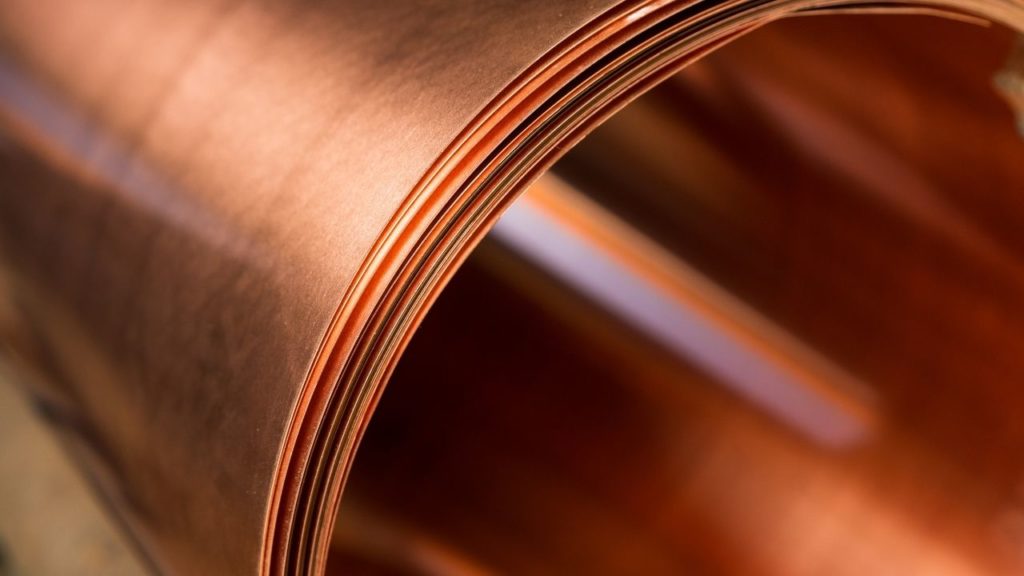

You don’t need to be an archaeologist to recognize that copper, #29 on the periodic table, has been #1 in our hearts. Humans have been harnessing this metal for over 10,000 years, with the same element in primitive pendants appearing in modern-day broadband infrastructure. From the Bronze Age to the Internet Age, the properties of copper have made daily life possible. What would happen if obtaining this metal were no longer possible? The thought is almost too much to bear.

Fortunately, copper is perhaps the most eminently recyclable metal in existence, as well as one that we can melt down and reform almost infinitely. The same copper that ran through the plumbing pipes of ancient Egypt may very well be within the copper fixtures of your own home. This is more than a fun fact—it’s a necessity. We need to make the most of copper’s recyclability for financial and ecological reasons alike. Today, we’ll examine both the environmental and economic advantages of recycling copper.

Essential Machines and Equipment for Scrap Metal Recycling

When you’re working in the scrap metal industry, you need the appropriate equipment to thrive. Some metal items are much heavier than others, making them dangerous or impossible for an individual to lift independently. As long as you’ve got the essential machines and equipment for scrap metal recycling, you’ll have what you need to collect and sort scrap metal.

Why It’s Important To Manage E-Waste

Take a trip back to 2001. Could you have imagined that you would have a flat computer screen that contains the entirety of your personal library? E-readers and tablets make it possible. Did you think you would have a cellular phone that you use for photography, video calls, note-taking, games, scanning your paychecks, playing music, and measuring your jogs—in essence, everything but making phone calls? (more…)

How Scrap Metal Recycling Has Changed In Recent Years

Some readers may be surprised to learn that the immigrants who got into the scrapping business out of sheer desperation successfully built operations that they’ve passed down to their children and grandchildren to this day. While scrap metal is indeed, in many cases, a family business, it’s a highly sophisticated family business, and it’s one that keeps evolving. Here are just a few examples of how scrap metal recycling has changed in recent years.

When To Repair and When To Replace Your Industrial Electric Motor

It’s an all-too-familiar scenario: your facility is humming along, when suddenly, some ominous sounds or untimely shutdowns herald a problem that’s going to take more than a moment of your time. You find that one of your electric motors has failed. Industrial machinery works hard, and just as human bodies often gave out under the burdens of hard labor, the machines we’ve designed to assist and replace us can fail as well. Even high-quality electric motors are prone to breakdown. Magnets can lose their charges, brushes can wear down, and other moving parts can simply stop moving as well as they need to. Whatever the reason, the upshot is the same—a critical piece of machinery is not able to do its job, and that means lost time, lost revenue, and high stress. (more…)

Common Myths About Scrap Metal Recycling

Operating on the peripheries of our towns and without bombardments of advertising on television and radio, the scrap metal business is a mysterious one to people whose businesses don’t deal with them regularly. If you’re just getting started in the industry yourself, you may carry a lot of the myths, misconceptions, and misinformation about the business of recycling. Let’s debunk three of the most common myths about scrap metal recycling and get to the truth.

Disposing of Metal on Your Construction Site

No builder likes to let materials go to waste. But in the process of cutting, shaping, and working with your materials, you still may find that you have a few leftovers—and that’s not even counting power tools. Leftover scrap metal is heavy, unwieldy, and takes up valuable storage space, and taking what’s left to the dumpster means a total loss when it comes to expenses. Fortunately, with conservation-minded strategies for disposing of metal on your construction site, no material ever truly goes to waste. You may be getting leftover metal off the premises, but rest assured it’ll end up being put to good use—even including those worn-out tools.

How To Make Scrap Metal Recycling More Efficient

Scrapping is all about turning trash into treasure. In some sense, all revenue from successful scrapping can be considered “found money”—in a more wasteful world, that material would end up in the garbage dumps never to be constructively reused again. In recycling, you should still seek to get the most out of scrap metal by generating the most revenue and consuming the smallest amount of energy. After all, part of what undergirds the scrapping industry is the conservation of resources. Here’s how to make scrap metal recycling more efficient—and more lucrative.

The Process of Recycling Metal

The metal recycling industry is growing rapidly. In fact, projections show that the metal recycling market will grow from 630.0 million tons to 890.7 million tons by 2025. In other words, there’s no question that there’s a growing demand for metal recycling for various reasons. One possible reason is the ever-growing demand for urbanization and manufacturing. Another possibility is that individuals and businesses in recent years have taken eco-friendly operations seriously, and rightfully so.

Why It’s Important to Recycle Metal

We all know that recycling at home is important for the environment, yet so many of us neglect that responsibility in our workplaces. Furthermore, industrial workplaces handle materials that we should always recycle. One of the most common materials is metal, so continue reading to learn why it’s important to recycle metal.

(more…)