Top Reasons To Recycle Aluminum

Your scrapyard deals with all sorts of metals. The ferrous mainstays, iron and steel, eventually prove their worth in sheer volume alone. But it’s the non-ferrous metals that you and your magnets are really looking for. Brass, zinc, copper, lead, and tin all offer value to recyclers. To that list, add aluminum, the lightweight but deceptively strong metal that goes into everything from soda cans to airplanes.

How Positive-Displacement Pumps Work

Varieties of fluids and applications call for varieties of pumps. Pumps, for the most part, can be divided into two groups based on how they send or displace fluid through piping systems. Centrifugal pumps use rotational energy to transport fluids, while axial-flow pumps use impellers within the pipes to move fluids along a vertical or horizontal axis. But perhaps the most common pumping mechanism is the positive-displacement pump, which captures and releases fluid to send the fluid on its way. In this guide, we’ll take a closer look at how positive-displacement pumps work.

Common Methods Used To Identify Metals

There’s no telling what will turn up at a scrap yard. You can happen upon some truly valuable pieces of metal in your yield, but their value may not immediately reveal itself to you. Scrap metal doesn’t come with labels in tidy packages. If it did, the job would be a lot easier. Instead, identifying a piece of metal falls on you, your equipment, and your own two eyes. With these common methods used to identify metals, you can ID your scrap and start separating the good stuff from the common iron.

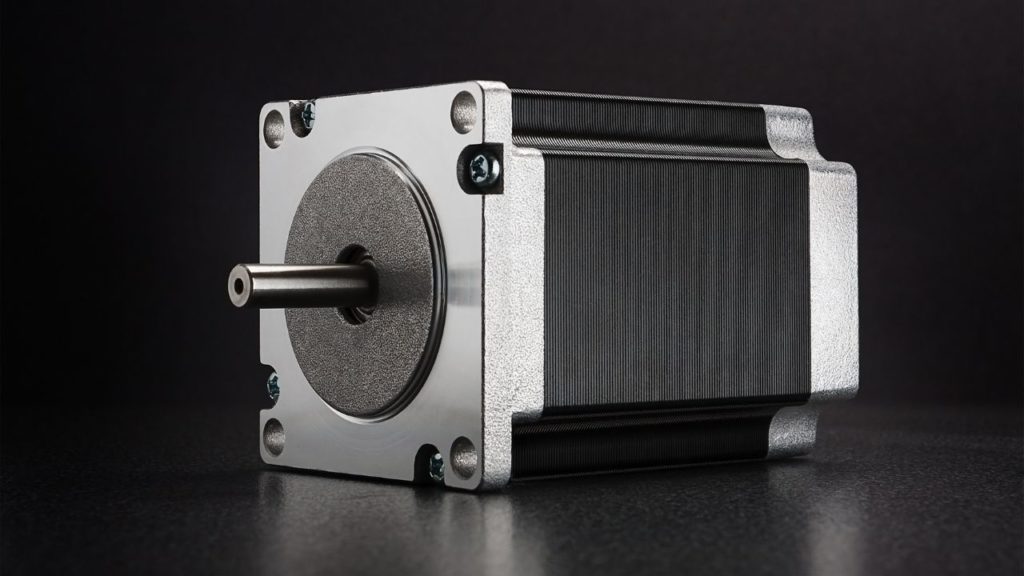

What You Should Know About Stepper Motors

Some jobs require you to take things one step at a time, and some jobs require that of the machinery as well. While many motors run simply as “on” or “off,” other motors for high-precision jobs work in discrete steps at the user’s command. We refer to these devices as stepper motors for their concentration on incremental work. Here’s a little of what you should know about stepper motors, from how they operate, to when they’re required, to when you’ll need to give them a closer look.

Typical Causes of Electric Motor Failure

Electric motors have arguably been the sole reason for increased efficiency and productivity in industries like manufacturing, automotive, construction, and so many more. By automating many processes, companies can allow the machinery to handle repetitive work and put the actual workers to better use elsewhere. While electric motors have undoubtedly made many jobs easier and streamlined a multitude of processes, these motors also require maintenance. Even if you regularly maintain your electric motor, there’s a possibility that you’ll experience a motor failure at some point. Luckily, failure doesn’t mean you need to replace your motor. In fact, there are some common reasons for electric motor failures. If you’d like to learn the typical causes of electric motor failure, we’ve got you covered. Continue reading to learn more.

(more…)

Top Tips For Maintaining Electric Motors

Electric motors have become a standard piece of equipment for many industries in recent years. These industries include construction, manufacturing, scrap yards, automotive, and more. Electric motors have become increasingly efficient over the years and have helped all these industries perform daily operations in a timely and reliable manner. However, many organizations make the mistake of neglecting maintenance, and then they can’t understand why their motors aren’t performing like they used to. In fact, without proper maintenance, some motors may be beyond repair and need a replacement. This not only increases a company’s expenses but will also increase their downtime and decrease productivity. The good news is all of these problems are preventable. Just continue reading our top tips for maintaining electric motors to learn how.

(more…)

Maintenance Tips

Plan for Downtime

It is imperative for shredders to be maintained regularly, especially within the waste industry, where a variety of materials is introduced into the shredder and processed at once. The best thing you can do for your operation to prevent large chunks of downtime is to routinely and thoroughly clean and maintain the shredding chamber. Rotating knives and replacing counter knives regularly is important to keeping the cutters sharp and performing optimally. One severely damaged knife can shut down a whole system if not dealt with proactively. Checking belts for wear and replacing them if necessary can also prevent any unwelcome surprises while the shredder is in operation.

Tips to Choose an Industrial Magnet Supplier

In recent years, industrial magnet suppliers have been popping up all over the nation making it difficult to choose the right supplier for the job. Whether you’re partnering with a supplier for the first time or you’re looking to change suppliers, our guide offers some tips to choose an industrial magnet supplier.

ISRI: New ingredients in the ferrous scrap mix

ISRI2018: New ingredients in the ferrous scrap mix

Making iron from raw materials may be one of the worlds longest-running manufacturing sectors, but the foundry industry in the last several decades has been infused with impressive amounts of change, according to Brett Fisher, a vice president with Wisconsin-based Neenah Foundry.

Another change during that same time has been an expansion in the types of gray and ductile iron produced by the foundry sector, with each new type of iron representing a different mixture of metallic alloys. (more…)

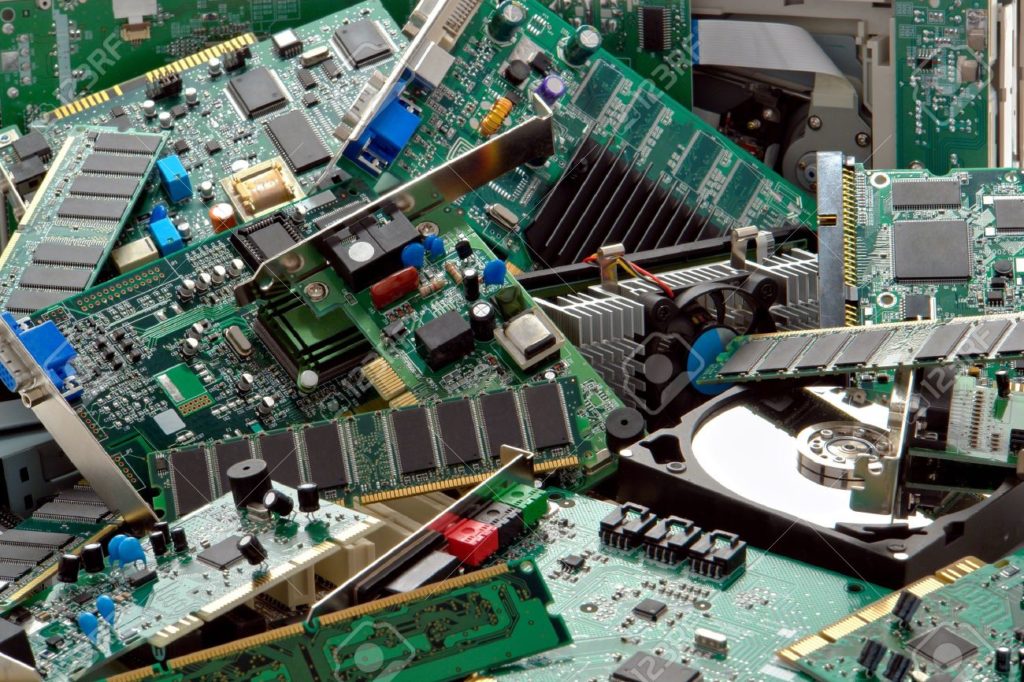

E-Waste News

E-Waste News: 13 times cheaper to extract metals from e-waste than to mine them.

A study published in Environmental Science & Technology this week finally has an answer, suggesting that urban mining of electronic waste for copper and gold in China was actually more cost-effective than digging those metals out of the ground.