How Electromagnets Work: The Basics

Today one of the most widely used industrial magnets are electromagnets because of their versatility and power-saving capabilities. Unlike permanent magnets, which have a constant magnetic field, electromagnets are only active when a power source is turned on. In most cases, the power source can vary from a generator to the motor on heavy equipment. Electromagnets changed the magnet industry for the better, but how exactly do electromagnets work? In our guide below, our experts explain how electromagnets work: the basics. Read on to learn more.

Top Magnetic Separator Safety Tips

Magnetic separators are one of the most beneficial machines for use in industries such as pharmaceuticals, scrap yards, food processing, and more. However, if users aren’t careful, magnetic separators can also cause several different types of injuries. Continue reading to learn the top magnetic separator safety tips.

(more…)

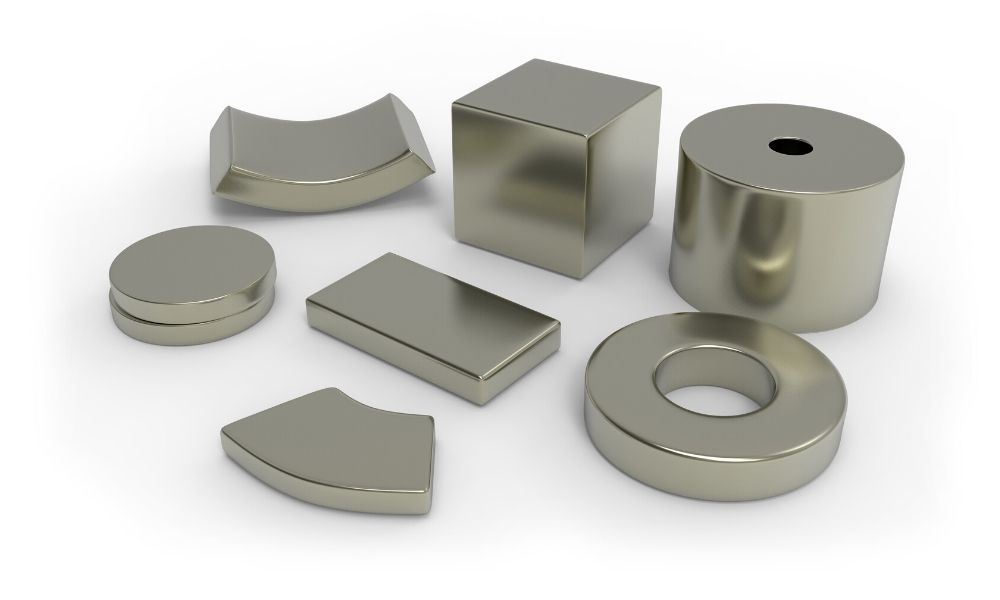

The Different Types of Permanent Magnets

Since the 1950s, permanent magnets have proven to be an essential piece of equipment in most industries. Between their versatility and ease of use, many companies find themselves investing in permanent magnets to increase efficiency, without having to do much training, if any. However, companies must decide which type of permanent magnet they want, and most important, the material used to manufacture the magnet. Continue reading to learn the different types of permanent magnets, which one is right for you, and why your company needs a permanent magnet.

(more…)

Considerations for Choosing a Crane Magnet

As an industrial worker or decision maker, you need the right equipment to work at your highest efficiency. Various pieces of heavy equipment help workers do their job to the best of their ability, and one of the most important machines is a crane. Whether you’re a scrapyard or working on a jobsite, crane magnets––or lifting magnets––are among the most useful attachments. Keep reading to learn some considerations for choosing a crane magnet.

(more…)

Maintenance Tips

Plan for Downtime

It is imperative for shredders to be maintained regularly, especially within the waste industry, where a variety of materials is introduced into the shredder and processed at once. The best thing you can do for your operation to prevent large chunks of downtime is to routinely and thoroughly clean and maintain the shredding chamber. Rotating knives and replacing counter knives regularly is important to keeping the cutters sharp and performing optimally. One severely damaged knife can shut down a whole system if not dealt with proactively. Checking belts for wear and replacing them if necessary can also prevent any unwelcome surprises while the shredder is in operation.

Considerations for Choosing a Magnetic Separator

Several industries have accepted magnetic separation as a method to reduce metal contamination in goods. Some of these industries include manufacturing, pharmaceuticals, food, and so on. If you work in any of these industries and don’t have a magnetic separation process, you’ve come to the right place. Keep reading for some considerations for choosing a magnetic separator.

(more…)

The Different Types of Railroad Attachments

Many individuals ride trains to get to and from work or to travel long distances for business or pleasure. In addition, companies still use trains to transport freight, finished goods, and raw materials, so railroad workers must maintain the tracks to ensure that trains can travel safely. There are multiple tools that railroad workers use, but nowadays they use machinery with a few different attachments to work more efficiently and save their backs. Below, we’ll cover the different types of railroad attachments that workers frequently use on their machinery.

(more…)

How to Know When to Use Plate Magnets

Several industries, such as the food and beverage, pharmaceuticals, manufacturing, and more, all need a magnetic separation process in place to avoid contamination. With that said, many organizations could largely improve their magnetic separation process simply by adding plate magnets in addition to their current magnet set up. People often ask how to know when to use plate magnets and by the end of this article, you’ll know a few signs that indicate you should incorporate plate magnets.

Magnetic Separation: The Basics

Magnetic separation has been around for decades, and people traditionally used electromagnetics for separation until permanent magnets became more available and affordable to produce. Industries such as scrap yards, mining, pharmaceuticals, biochemistry, manufacturing, and food all use magnetic separation regularly because it’s effective and efficient. However, it’s important to have a general understanding of magnetic separation, how it’s used, and the types of magnets. Our guide of magnetic separation: the basics, will break it all down.

(more…)