Rail Construction Frequently Asked Questions (FAQ)

Rail construction is a intriguing and complex process that plays a critical role transportation today. Whether you’re a railway enthusiast or just curious about how the tracks beneath a train come into existence, this guide will take you on a journey through the world of rail construction.

Materials Used in Rail Construction

Rail construction begins with the careful selection of materials. High-quality steel is the critical component of any railway track, ensuring durability and stability. The rails are complemented by wooden or concrete sleepers, providing a solid foundation.

Techniques Employed in Rail Construction

Precision is integral in rail construction. The alignment of tracks, proper welding of joints, and meticulous ballasting are essential steps to guarantee a smooth and safe ride. Advanced machinery and technology play an important role in achieving these high standards.

Environmental Considerations

Rail construction is not just about building tracks; it’s also about minimizing environmental impact. Engineers use eco-friendly materials and implement measures to reduce noise and vibration, making rail travel a sustainable choice.

FAQs (Frequently Asked Questions)

Q. What is rail construction?

A. Rail construction is a complex and multifaceted process that requires collaboration between engineers, construction crews, and project managers. The goal is to create a reliable and sustainable rail network that facilitates the efficient transportation of goods and passengers.

Q. How long does it take to construct a railway track?

A. The timeline for rail construction varies based on factors such as distance, terrain, and project complexity. On average, a mile of track can take several weeks to complete.

Q. What safety measures are in place during rail construction?

A. Safety is non negotiable. Rail construction sites adhere to strict safety protocols, including protective gear for workers, warning signs, and secure barricades to prevent accidents.

Q. How often do rail construction equipment undergo maintenance?

A. Maintenance schedules vary, but regular checks and servicing are performed to ensure the equipment operates at peak efficiency and safety.

Q. What kind of equipment is used for rail construction?

A. Many pieces of equipment are needed during rail construction and maintenance including track laying machines, ballast regulators, tamping machines, rail breakers, inspection cars, excavators and bull dozers.

Conclusion

In conclusion, rail construction is a meticulous blend of science, engineering, and environmental consciousness. As we continue to advance in technology, the future of rail construction holds exciting possibilities. From maglev trains to sustainable materials, the evolution of railways is a journey worth tracking.

Moley Magnetics sells attachments to support the rail, reach out to us today.

Check out video on our YouTube channel.

Excavator Magnet: Modernizing Construction Efficiency

In the evolving world of rail construction and excavation, the role of technology continues to evolve, with innovations constantly reshaping industry standards. One such groundbreaking technology that has gained prominence in recent years is the excavator magnet. In this article, we will explore the functionalities, advantages, and real-world applications of the excavator magnet, exploring how it has become a game-changer in enhancing construction efficiency.

Understanding Excavator Magnet Technology

An excavator magnet is a powerful and versatile attachment designed to be fitted onto the boom of an excavator. When the excavator is outfitted with a powerful magnet, it operates by generating a strong magnetic field that attracts and securely holds ferrous objects. This technology has proven to be particularly valuable in various construction scenarios where efficient handling of metal debris is critical.

The Dynamics of Excavator Magnets

Excavator magnets come in different sizes and options for power, allowing for adaptability to various excavator models and job requirements. The magnetic systems within these attachments are engineered to efficiently lift and transport metal objects, ranging from small ferrous materials to larger pieces, with accuracy and ease.

Advantages of Excavator Magnets in Rail Construction

Increased Efficiency in Debris Handling

One of the primary advantages of employing an excavator magnet is the significant improvement in debris handling. Construction sites often accumulate metal fragments, nails, rail plates and other ferrous materials that can impede progress. The excavator magnet streamlines the cleanup process, allowing for swift and thorough removal of these materials, thus reducing downtime and enhancing overall efficiency.

Time and Labor Savings

The efficiency gains brought about by excavator magnets translate directly into time and labor savings. Specifically, rail construction projects are notorious for their tight schedules, and any tool that expedites the process contributes to meeting deadlines and staying within budget constraints. With an excavator magnet, manual labor for collecting metal debris is minimized, freeing up human resources for more intricate tasks.

Enhanced Safety Measures

Safety is critical in the construction industry, and excavator magnets play a crucial role in creating a safer work environment. By minimizing the need for manual handling of metal objects, these attachments reduce the risk of injuries associated with lifting heavy or sharp materials. This enhancement in safety contributes to a positive overall project outcome and promotes a secure workplace.

Real-world Applications of Excavator Magnets

Construction Site Cleanup

Excavator magnets find extensive use in construction site cleanup operations. Whether it’s removing nails, screws, or other metal debris from demolition sites or clearing the ground for new construction, the magnet’s efficiency simplifies the cleanup process, ensuring a clean and hazard-free workspace.

Scrap Metal Recycling

Beyond construction sites, excavator magnets are integral in the recycling industry, particularly in the handling of scrap metal. Excavators fitted with magnets can easily pick up ferrous materials from piles, segregating them efficiently for recycling purposes. This not only contributes to sustainable practices but also streamlines the recycling workflow.

Future Trends and Innovations

As technology continues to advance, the future of excavator magnets holds exciting possibilities. The integration of smart technologies, such as sensors and automation, could further enhance the precision and capabilities of these attachments. Additionally, ongoing research and development may lead to the creation of even more powerful and efficient excavator magnets, expanding their range of applications.

Conclusion

In conclusion, the excavator magnet has proven to be a transformative technology in the rail construction and excavation landscape. Its ability to efficiently handle metal debris, increase productivity, and enhance safety measures positions it as an asset on construction sites. As we look to the future, the continuous evolution of excavator magnet technology promises even greater contributions to the efficiency and sustainability of construction practices.

See our video on YouTube

When A Magnet Grapple Is Used On The Railroad

In the evolving landscape of railroad technology, magnet grapples have emerged as a game-changer, changing the way we approach railroad construction, maintenance and operation. As we explore the applications of the magnet grapple on the railroad, we can see the impact that goes beyond standard methods.

Embracing Innovation

In a world where technological advancements shape industries, magnet grapples stand out as proof to innovation. Their application extends far beyond initial expectations, making them essential in sectors such as construction, manufacturing, and notably, the railroad industry.

Significance in Railroads

Railroads serve as the lifelines of transportation, requiring thorough care and maintenance. A magnet grapple brings efficiency and accuracy to this fundamental sector, offering a unique set of advantages that redefine the standards of rail infrastructure management.

Unveiling the Focus

This article focuses on the use cases of magnet grapples within the railroad industry. From understanding the technology to exploring real-world applications, we will study the layers of benefits that magnet grapples bring to the tracks.

Understanding a Magnet Grapple

Functionality at a Glance

Magnet grapples, equipped with powerful magnets, operate by attracting and securely gripping metallic objects. This functionality proves instrumental in diverse applications, including the sophisticated world of railroad construction and maintenance.

Types of Magnet Grapples

Diverse scenarios demand varied solutions. We explore the different types of magnet grapples tailored for railroad use, considering factors such as track material, weight capacity, and operational requirements.

Advantages on Railroad Tracks

The unique characteristics of a magnet grapple make it particularly suited for railroad applications. From efficient debris removal to streamlined maintenance processes, their advantages go beyond the surface.

Use Cases in Railroad Industry

Track Maintenance Efficiency

The magnet grapple plays a pivotal role in enhancing the efficiency of track maintenance operations. Their ability to quickly and precisely pick up metal fragments expedites the process, minimizing downtime and ensuring seamless rail operations.

Debris and Metal Object Removal

Railroads often face challenges related to debris accumulation and stray metal objects. A magnet grapple offer a solution by efficiently removing these obstacles, contributing to a safer and more reliable rail network.

Safety Enhancement

Safety is paramount in the railroad industry. Magnet grapples contribute to a safer working environment by reducing the manual handling of potentially hazardous materials, thereby minimizing the risk of accidents.

Benefits of Magnet Grapples

Productivity Boost

The adoption of magnet grapples translates into increased productivity. The swift and precise handling of metal objects means less time spent on manual labor, allowing rail crews to focus on more critical tasks.

Cost-Effective Solutions

When spending money efficiently and effectively is necessary, the magnet grapple emerges as a financially prudent choice for railroads. Their efficiency in handling maintenance tasks translates into long-term savings for rail operators.

Environmental Friendliness

Beyond efficiency and cost-effectiveness, magnet grapples contribute to environmental sustainability. By reducing the need for extensive manual labor and reducing the environmental impact of debris, they align with green practices.

Future Prospects

Emerging Trends

As technology evolves, so do the prospects of magnet grapple applications within the railroad industry. We explore emerging trends that could further enhance the capabilities of these tools, paving the way for even more efficient rail operations.

Advancements in Railroads

Beyond the immediate application of magnet grapples, we consider broader advancements within the railroad industry. The associated relationship between technology and rail transportation unfolds, with magnet grapples playing a crucial role.

Future Role of Magnet Grapples

Speculations on the future role of magnet grapples in rail transportation hint at their continued significance. From increased automation to integration with other smart technologies, the possibilities are endless.

Conclusion

Summarizing Significance

In conclusion, the impact of magnet grapples on the railroad industry is undeniable. From streamlining maintenance processes to contributing to a safer rail environment, their significance cannot be overstated.

Do you want to learn more? Check out our related article and our website www.moleymagneticsinc.com

Check out our video on YouTube

24 Volt Magnets: Changing Rail Construction

The world of railroads is witnessing a quiet revolution, and at the core of this transformation lies the power of 12/24 and 24 volt battery magnet systems. attachments play a critical role in the efficient and safe functioning of construction and maintenance for railways, and understanding their significance is key to the future of this method of transportation.

Understanding 12/24 and 24 Volt Magnet Systems

These magnets are powered by a 12/24 or 24 volt electric charge, are becoming a linchpin in the transformation of railroad systems construction. Basically, they function by creating a magnetic field, which offers several advantages in railway applications. The magnets’ ability to attract or repel, based on the electric current running through them, makes them a fundamental component in various railroad operations.

How 12/24 and 24 Volt Magnets Improve Safety

Safety stands as a vital concern in rail transportation. These magnets aid in ensuring precise control over the movement of material on the rail. Their reliability in moving materials efficiently and safely is paramount maintaining a safe travel environment.

Energy Efficiency and Environmental Impact

With the focus on energy-efficient equipment, the utilization of 12/24 and 24 volt battery magnet systems in railways is a game-changer. By reducing reliance on fossil fuels, these magnets help in creating greener and more sustainable railway maintenance and construction, thus contributing to the global efforts in combating climate change.

Installation and Functionality

The installation of 12/24 and 24 volt magnet systems on maintenance of way trucks and excavators involves strategic placement. Their functionality seamlessly integrates with the equipment they are installed on, offering a reliable and sturdy solution to ensure the smooth operation of rail construction and maintenance .

Maintenance and Durability

Maintaining these magnets is essential for ensuring a long life. Regular checks and maintenance routines should be in place to guarantee their durability, reliability and consistent performance, reducing the likelihood of operational disruptions.

Advancements in Battery Magnet System Technology

Ongoing research and advancements in magnet technology continue to enhance the efficacy of 12/24 and 24 volt magnet systems. Innovations are focused on improving their strength, durability, and operational capabilities, promising even more reliable and efficient railway systems.

The Future of 12/24 and 24 Volt Magnets Systems in Railroads

The future of railroads undoubtedly leans on the utilization and advancement of 12/24 and 24 volt battery magnet systems. As technology progresses, these magnets will play an increasingly vital role in the efficiency of construction and maintenance, safety, and environmental sustainability of railways, shaping the future of transportation.

Conclusion: Embracing the Magnetic Future

In conclusion, the integration of 12/24 and 24 volt battery magnet systems in railroads marks a milestone in the evolution of railway systems. Their diverse advantages in safety, energy efficiency, and functionality showcase the transformative potential they hold, promising a future where rail transportation is not only efficient but also environmentally friendly.

Rail Construction: A Sustainable Future

In today’s changing world of logistics and transportation, the construction and maintenance of freight rail networks have become important elements in the supply chain. Let’s explore the world of freight rail construction and maintenance, with a focus on sustainability and the innovative practices that are shaping the industry.

The Significance of Freight Rail Construction and Maintenance

A Pillar of Global Trade

Freight railroad construction and maintenance serves as the pillar of global trade and commerce. The transportation of products and raw materials, often in large quantities, requires an efficient and eco-friendly mode of transportation. By prioritizing sustainability in freight railroad construction, there is a smooth flow of delivery of goods while minimizing the impact to the environment.

Decreasing Emissions

Reducing carbon emissions is a global imperative. Freight rail systems, when constructed and maintained sustainably, play a crucial role in achieving this goal. Trains are already among the most fuel-efficient means of cargo transport, and sustainable rail construction enhances this advantage.

Efficient Cargo Movement

The importance of efficient cargo movement cannot be overstated. Sustainable track construction ensures that products move from point A to point B quickly, reliably, and economically. This efficiency translates into cost savings for businesses and a reduction in road congestion, ultimately benefiting both the economy and the environment.

Sustainable Practices in Freight Railroad Construction

Environmentally Friendly Materials

Sustainability starts with the materials used. Locally-sourced and recycled materials are prioritized to reduce the environmental impact. This focus on an environmentally friendly approach lessens the burden on natural resources and reduces waste, supporting the economy.

Energy-Efficient Design

Energy efficiency is a cornerstone of sustainable freight railroad construction and maintenance. By adopting energy-efficient construction methods and technologies, rail systems can significantly reduce their energy consumption, which, in turn, leads to lower greenhouse gas emissions. This means less reliance on fossil fuels.

Minimize Waste Reduction

Sustainable construction minimizes waste. By carefully managing construction waste and reusing materials, the industry lessens the strain on landfills and contributes to resource conservation. This waste reduction not only benefits the environment but also saves costs in waste disposal.

Sustainability and Cargo Transport

Electrification and Hybrid Solutions

The electrification of freight rail systems is a significant step towards reducing emissions, and is a way that rail is helping to lead the way in waste reduction. There are recent industry discussions taking place that suggest that electric and hybrid locomotives can be more eco-friendly alternatives to traditional diesel engines, resulting in cleaner and more sustainable cargo transportation. These technologies are also quieter, reducing noise pollution along rail routes.

Efficient Freight Hubs

Sustainable rail construction and maintenance extends to the development of efficient freight hubs. These hubs are strategically designed to minimize the distance between railroads and warehouses, reducing the need for long-haul trucking and further curbing emissions. Efficient freight hubs play a vital role in streamlining the supply chain, and significant efforts have been devoted to transportation logistics with an eye toward enhancing efficiency and reliability.

Digitalization and Smart Logistics

The integration of smart technologies into freight rail systems optimizes cargo movement. IoT sensors, real-time data analytics, and smart logistics solutions enhance scheduling, maintenance, and energy consumption. This, in turn, contributes to the overall sustainability of the industry and ensures reliable and environmentally responsible cargo transport.

Economic Benefits of Sustainable Freight Rail Construction

Job Creation

Sustainable freight railroad construction projects creates employment opportunities across various sectors, from construction and engineering to maintenance and operations. These projects stimulate local economies by creating jobs and supporting skilled labor. It’s not just about constructing railroads; it’s about building communities.

Cost Savings

Investing in eco-friendly materials and energy-efficient designs may involve upfront costs, but they result in long-term cost savings. Reduced maintenance expenses and operational efficiencies make sustainable freight rail systems economically advantageous.

Attracting Investment

Sustainable freight rail systems attract both private and public investments due to their long-term viability and reduced environmental impact. Investors increasingly favor projects that align with sustainable development goals, making the industry a favorable choice for funding. This interest in sustainability drives further innovation and progress in the sector.

The Future of Freight Rail Construction

Expansion of Sustainable Freight Rail Networks

The future of freight rail construction is geared towards expanding sustainable networks. These networks not only facilitate the efficient transport of goods but also reduce emissions and decrease the environmental impact of cargo transportation. Expansion includes the development of new routes and the modernization of existing ones to meet evolving sustainability standards.

Integration of Renewable Energy

The integration of renewable energy sources, such as solar and wind power, into freight rail networks is on the horizon. This innovation decreases the industry’s dependence on fossil fuels and enhances sustainability. The rail industry is positioned to become a significant player in the transition to a cleaner energy mix.

Smart Logistics in Cargo Transport

The development of smart cities will lead to increased integration of rail systems with other modes of transportation, offering a seamless and eco-conscious supply chain solutions. By seamlessly connecting rail with road, air, and sea transport, cities can further reduce emissions and congestion, contributing to a greener urban landscape.

The Role of Moley Magnetics and Equipment

In the pursuit of sustainable freight rail construction, companies like Moley Magnetics and Equipment play a vital role. Their expertise in providing solutions such as 12/24 and 24 volt battery magnets systems, railbreakers, railroad battery magnets, hydraulic generators, and excavator magnets contributes to the efficiency and environmental responsibility of railroad construction. These specialized tools enhance the industry’s ability to build, maintain, and operate rail systems in an eco-friendly manner.

Conclusion

Freight railroad construction and maintenance is not just about laying tracks; it’s about leading the way for a more sustainable and efficient transport system. By embracing eco-friendly materials, reducing emissions, and integrating smart technologies, the industry is at the forefront of creating a greener and more efficient future for the world of logistics.

The next time you see a freight train passing by, watch the maintenance of a track underway, or witness the construction of a freight rail network, remember that they are part of a larger effort to build a more sustainable and environmentally responsible approach to transporting goods. Freight railroad construction is more than just logistics; it’s the foundation of a more sustainable cargo transportation industry, and its future is bound to be both green and prosperous.

Related Articles

Railbreakers: Transforming Maintenance

How to Safely Use Railroad Repair Equipment

The Equipment Needed for Railway Construction

24 Volt Magnets Changing Rail Construction

When a Magnet Grapple is Used on the Railroad

Excavator Magnet: Modernizing Construction Efficiency

Rail Construction Frequently Asked Questions (FAQ)

Hydraulic Magnet Generators: Scrapyard Operations

Railbreakers: Transforming Maintenance

Introduction

Railbreakers play a fundamental role in railway infrastructure, as they facilitate not only track maintenance but also various rail construction, maintenance and demolition activities. These powerful attachments are equipped with safety features to ensure the protection of operators and maintenance crew during operation. Their precision and force allow controlled rail cutting or breaking, making them essential tools in the hands of experienced professionals.

The use of railbreakers has transformed the efficiency of railway maintenance, allowing for quicker repairs and upgrades. Their versatility and robustness makes them indispensable in the ever-evolving landscape of transportation infrastructure, contributing to the safety and functionality of railway systems across the globe.

Evolution of Railbreaking Technology

The history of railbreakers traces back to the industrial revolution, where basic tools were initially employed to dismantle, maintain, and re-lay railway tracks. Over time, technological advancements have led to the development of advanced and powerful railbreaking equipment.

In the mid-20th century, hydraulic railbreakers emerged, revolutionizing the rail maintenance industry. These innovations drastically improved the efficiency and safety of track maintenance, setting the stage for further technological advancements.

Market Growth

The railbreaker industry has experienced remarkable growth in recent years, owing to the increasing demands in railway maintenance and infrastructure development. With the expanding railway networks worldwide, the need for efficient railbreaker technology has become evident. This growth is expected to continue as global transportation and delivery of goods expands and the need for effective track maintenance increases.

Environmental Impact

As environmental concerns grow, the industry has responded with eco-friendly railbreaker models. Manufacturers are increasingly focused on developing equipment that minimizes environmental impact by reducing emissions and noise pollution.

Sustainable Practices

Apart from eco-friendly models, the industry is also embracing sustainable practices in railbreaker operations. These practices include the use of biodegradable hydraulic fluids, energy-efficient systems, and the adoption of recyclable materials in manufacturing, aiming to reduce the overall carbon footprint.

Conclusion

In summary, railbreakers are necessary in railway construction, maintenance, and demolition. The evolution of these powerful machines, their diverse applications, and the positive impact on safety and efficiency continue to drive the industry forward. As technology progresses, the future of railbreakers promises even greater advancements and a positive shift in the way we manage our rail systems.

See the Moley Magnetics & Equipment Railbreaker on YouTube

Lower Your Tax Burden in 2023 with Section 179

At Moley, we understand the importance of making informed decisions that benefit your business. With the year-end approaching, we want to inform you of US Tax Code Section 179, a U.S. tax law designed to encourage businesses buy equipment and invest in themselves. Section 179 allows businesses to deduct 80% of the purchase price of qualifying equipment purchased or financed during the tax year, reducing overall income tax liability.

For the 2023 tax year, the deduction limit is $1,160,000. Additional detailed information can be found at the IRS website or by contacting your accountant or financial advisor.

If you decide that Section 179 can benefit you, it’s best to act now, as it is our understanding the equipment must be purchased, delivered and put into service by December 31, 2023. The clock is ticking on taking advantage of this US Tax Law for 2023; reach out to Moley to buy the equipment you need today! We have a strong backing of inventoried products, so click on the links below to our product pages for more information on 230 volt scrap magnets, battery magnets (no magnet, generator needed) hydraulic magnets, orange peel grapples, scrap shears, magnet generators and concrete pulverizers!

Please note that this post does not constitute any tax advice, and you are encouraged to consult with your accountant or tax advisor regarding Section 179.

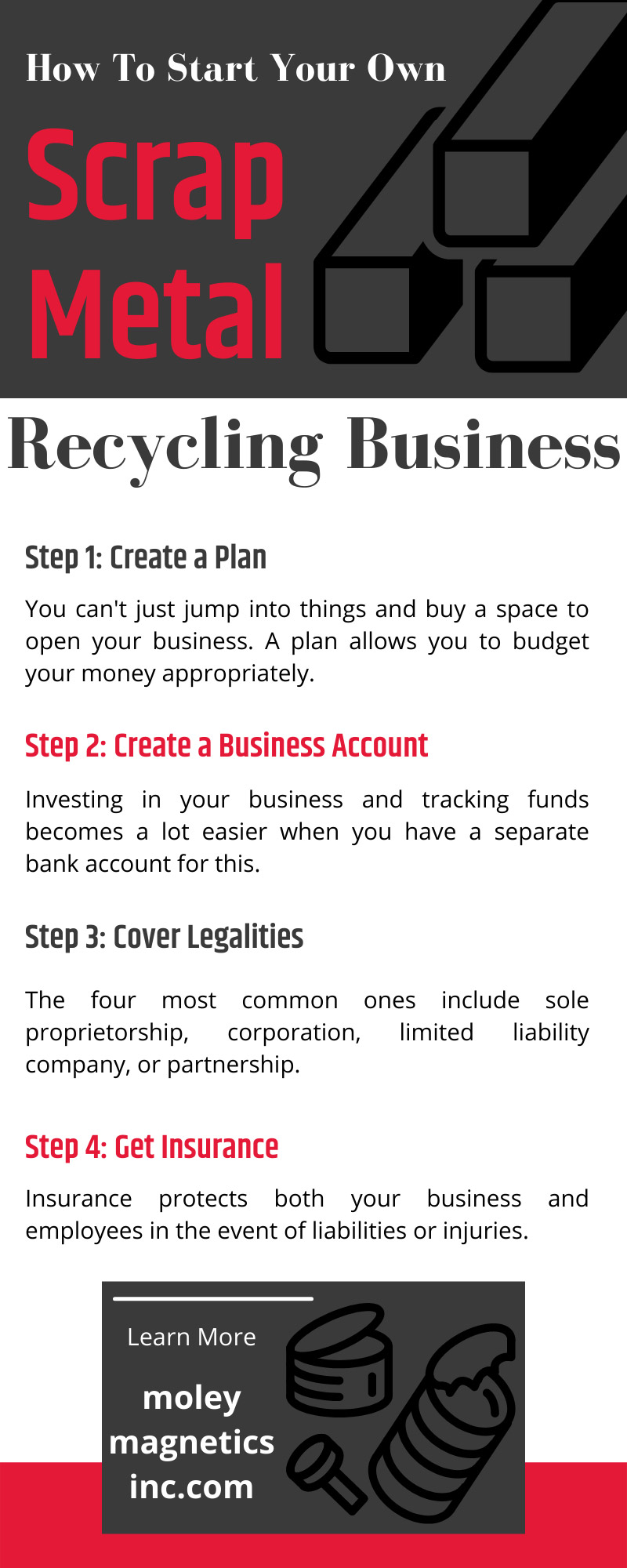

How To Start Your Own Scrap Metal Recycling Business

As environmental awareness increases, so does the need for more metal recycling companies. After all, various industries—automotive, appliance, construction, etc.— produce scrap metal, so we need someone to recycle it. Get the advice you need in this article on how to start your own scrap metal recycling business in just a few simple steps.

Step 1: Create a Plan

You can’t just jump into things and buy a space to open your business. A plan allows you to budget your money appropriately. Consider the following:

- Decide on a target market: What industries do you most want to sell to?

- What amount you’ll pay sellers: What will you pay in exchange for scrap metal?

- What you charge: How much will ingots cost once you resell the scrap?

- Business name: How will your business name help you stand out?

- Equipment: What kind of excavators, material handlers, excavator scrap shears, scrap yard magnets or waste handling grapples are needed?

Owning a business isn’t easy and requires a lot of planning and understanding of your industry. Investigate the ongoing cost for various metal types, so you pay and charge partnering businesses appropriately.

Stick To a Budget

One of the first things you should do as you plan is to create a budget. How much money will you initially invest into the business? Your starting budget should cover the cost of land, machinery, transportation, employee pay, and more. Avoid making those big-ticket purchases right away if you don’t have to, and focus on purchasing the necessities instead.

Remember Ongoing Expenses

You should also note those ongoing expenses like taxes, payroll, and insurance as you create your budget. These unavoidable expenses can build up in a hurry.

Understanding Your Target Market

When it comes to a target market, you’ll have to decide what types of metal you’ll scrap as this will impact the types of businesses you will work with. For example, if you only scrap iron-based material, you can only sell it to those who will use it.

Additionally, the type of metal you decide to scrap impacts how much you’ll sell it for—you’ll make more money selling copper than you would aluminum, but it may be harder to obtain in your area.

Naming Your Business

Naming your business is among the most important parts of ownership, so take time to do so. You’ll want something easy to remember but also fresh in the customer’s mind. Once you settle on a name, you’ll need to ensure no other business already has claims to it, and if not, register it for yourself.

Step 2: Create a Business Account

Investing in your business and tracking funds becomes a lot easier when you have a separate bank account for this. This way, you can also invest in new assets and track other expenses you make without worrying about it getting intermixed with your personal spending.

Pro Tip

When you open a business account, get a credit card for the company. This way, you can charge expenses such as tools and machinery to a single account that is easy to track and helps improve your company’s credit history.

Step 3: Cover Legalities

When the time comes to register your business, you’ll have to decide what type of business structure you’d like to implement. The four most common ones include sole proprietorship, corporation, limited liability company, or partnership.

After settling on a business structure, you’ll also have to register for taxes—you’ll do this after picking a business structure since that impacts how you’ll pay. This is also where having a business account at the bank comes into play. When the time comes to file your taxes, it’s much easier to note your expenses and determine what you can write off when business and personal money remain separated.

Obtaining Licenses

Finally, you’ll also need to obtain the required permits and licenses so you can open a shop, such as a metal recycling license and a Certificate of Occupancy.

Since you’ll buy and resell metal, you’ll need the appropriate license to do so legally. Almost every state requires businesses in your industry have a metal recycling license to ensure you follow legal measures throughout the life of your business. If you don’t know what licenses you need, contact your city clerk’s office for further information.

Step 4: Get Insurance

You’ll need insurance for both your business and employees, so you’ll have to decide on which policies you prefer. You may find some that are out of your price range, so keep your budget in mind as you look around for what’s best. Insurance protects both your business and employees in the event of liabilities or injuries.

Step 5: Purchase the Essential Tools

One of the most important parts of knowing how to start your own scrap metal recycling business is gathering the necessary tools. Before you begin collecting scrap, you should purchase the appropriate tools and equipment, so you don’t wind up with piles of scrap metal and no way to recycle it. You’ll need:

- Company vehicles to transport scrap

- Storage facilities for scrap and ingots

- Toolbox with wrenches, screwdrivers, etc.

- Power drills and drill bits to disassemble materials

- Wire granulators to separate wire from casing

- Scrap yard magnets to separate ferrous from non-ferrous metals

In addition to this, employees should have the protective gear so they can safely handle all metals throughout the recycling process. By having all of this before officially opening up shop, you’ll be completely prepared, and your team of workers can complete tasks more efficiently.

Pro Tip

Buy your scrap yard magnet, waste handling grapple or excavator scrap shear and other machinery for recycling from Moley Magnetics. As industry leaders, see we’ve got all the high-powered equipment you need to make your business a thriving success!

Step 6: Begin Collecting Scrap

Once you’ve covered all the essentials, it’s finally time to open your doors and begin collecting scrap. Consider marketing yourself online or contacting local businesses working in the metal industry to see if they have metal to recycle.

The more you advertise your business, the more likely you are to attract new customers, and as you work with these companies, you can build relationships. As you establish these relationships, ask for references to further expand your services throughout the community.

3 Mistakes To Avoid When Sorting Your Scrap Metal

Recycling scrap metal isn’t as simple as saying goodbye and tossing it in the recycling bin. First, you’ll have to sort out the various metal types to ease the process. As you do this, it’s best to note the common mistakes to avoid when sorting your scrap metal. By keeping yourself and your employees aware, scrapping metals becomes much more manageable.

Failing To Understand the Values of Metals

One of the most important things to note is that some metals are more valuable than others. While this can depend on supply and demand economics, specific materials like copper are always highly valued. Having a thorough understanding of the values of various scrap metals sets your business up for success.

Not Separating Your Metals

Forgetting to separate metals is another common mistake to avoid when sorting your scrap metal that could mean making less money when you take it to the scrap yard. For example, copper and non-ferrous metals sell at a higher price. By taking time to sort this out, you make it easier to sell your scrap for a fair amount of money.

Use an industrial magnet or a Moley Magnetics 2 in 1 sorting claw magnet to sort out your metals since this allows you to separate magnetic material from non-magnetic. By separating these, you can sell each for the individual price. If a specific metal has a lower value than expected, hold onto it until prices increase. At Moley Magnetics, you can purchase a scrap yard magnet to keep sorting simple.

Forgetting Scrap Yard Requirements

When it comes to sorting your scrap metal, one of the first things you should do is investigate the scrap yard’s requirements for metal types plus other rules. Next, aim to establish a relationship with a single scrap metal recycling center, so you always understand their recycling rules.

This could differ from company to company, and the best way to get clarification is by contacting the business and asking about what rules they have. For example, some companies may specialize in recycling a specific type of scrap, but others may not be so picky.

Pro Tip

As you establish a relationship with a scrap yard, ensure the business is reputable. A trustworthy recycling company will give you a fair price for your scrap, while also correctly recycling it so others can eventually reuse it.

Make separating your metals easy by purchasing high-powered industrial magnets from Moley Magnetics. Once you’ve expertly separated all your materials, sell them for the best prices. By tracking those profits, you make it simple to reinvest in your business with updated tools and machinery that make tasks easier.

Eco-Friendly Material: What Makes Stainless Steel Sustainable

Going green has become the key to success for many companies, both financially and in terms of boosting their reputation. By reusing resources, we conserve both natural and unnatural resources, which can improve overall environmental awareness. But are some resources better to use than others? The fast answer is yes.